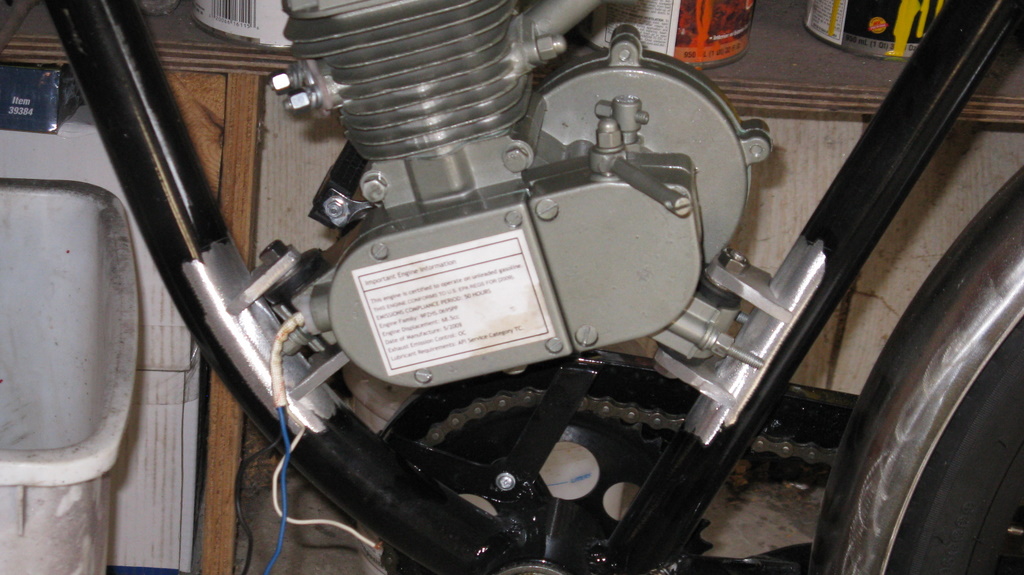

Just got the motor in yesterday. Before I tear it down and start blue printing and building it, I decided to install it and get a good base line.

The frame is a walmart $85 Ocean Pacific beach cruiser. Forks are something I built out of some pit bike tripple tree parts and steel tubing I welded up, bent up a fender and slapped that on.

Decided to go with a soft mount setup, so I cut out some tabs and welded them up. Deffinately have to go to a harder durometer rubber next time as these are too soft, the motor torques sideways a bit when starting.

Still have to hide the wires and other cables but you get the general Idea. Its getting torn down either tomorrow or the next day to start blue printing.

The frame is a walmart $85 Ocean Pacific beach cruiser. Forks are something I built out of some pit bike tripple tree parts and steel tubing I welded up, bent up a fender and slapped that on.

Decided to go with a soft mount setup, so I cut out some tabs and welded them up. Deffinately have to go to a harder durometer rubber next time as these are too soft, the motor torques sideways a bit when starting.

Still have to hide the wires and other cables but you get the general Idea. Its getting torn down either tomorrow or the next day to start blue printing.