AussieSteve

Active Member

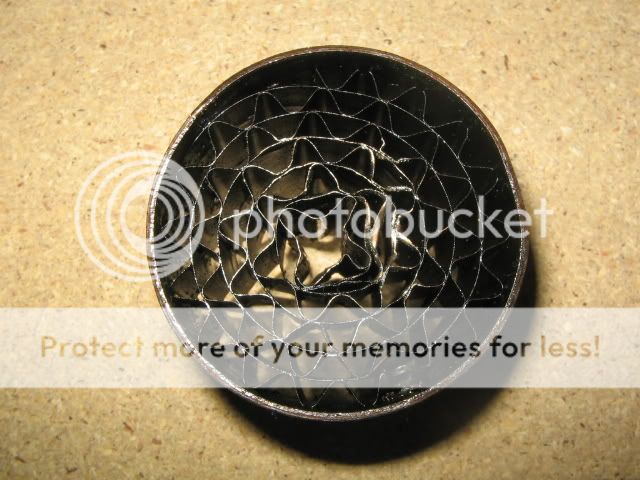

I've been reading through old threads on the usual HT muffler mods, (holes drilled in outlet pipe or pipe cut off altogether), but the results seem inconclusive.

Some say that they had a dramatic improvement, others little or none, while others said there was initially no change, but following up by jetting richer improved performance.

In all cases, of course, noise increases.

Are these mods more likely to increase top or bottom end power, if any increase at all?

If there is an improvement, is it worth cutting the outlet pipe short, then stuffing the tail of the muffler loosely with stainless steel pot scourers to reduce noise, or is this just likely to bring the restriction back up to where it was originally?

Any thoughts on this subject?

... Steve

Some say that they had a dramatic improvement, others little or none, while others said there was initially no change, but following up by jetting richer improved performance.

In all cases, of course, noise increases.

Are these mods more likely to increase top or bottom end power, if any increase at all?

If there is an improvement, is it worth cutting the outlet pipe short, then stuffing the tail of the muffler loosely with stainless steel pot scourers to reduce noise, or is this just likely to bring the restriction back up to where it was originally?

Any thoughts on this subject?

... Steve