calpolymike

New Member

I have searched here and nobody seems to have one.

anyone??? anyone??

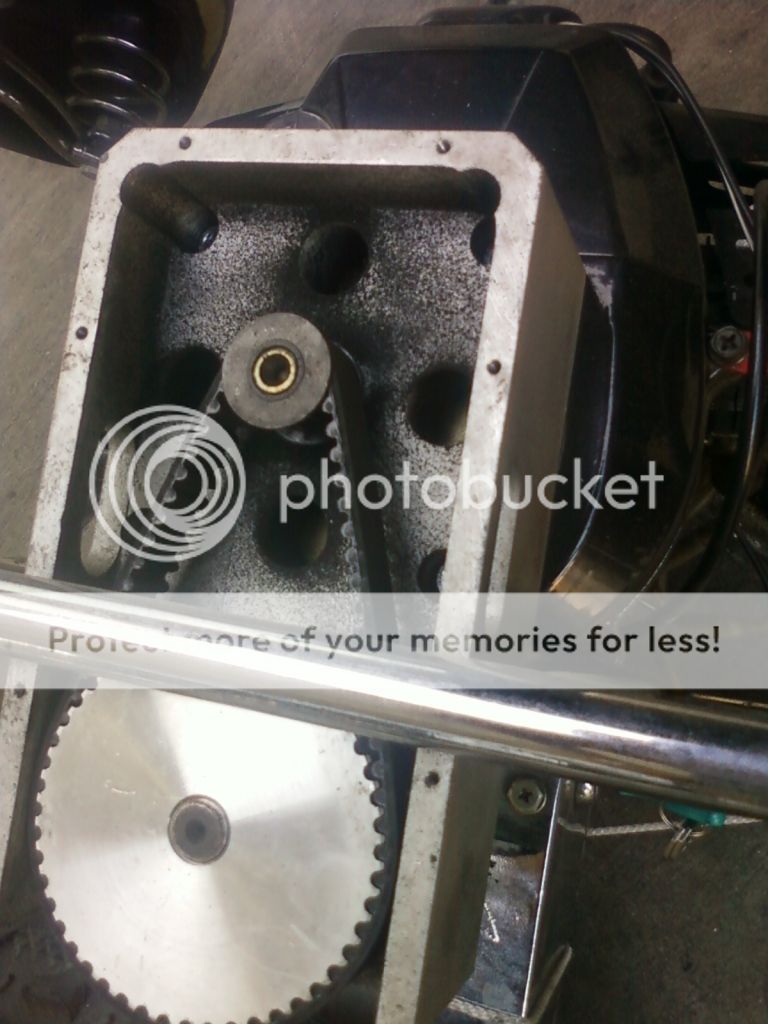

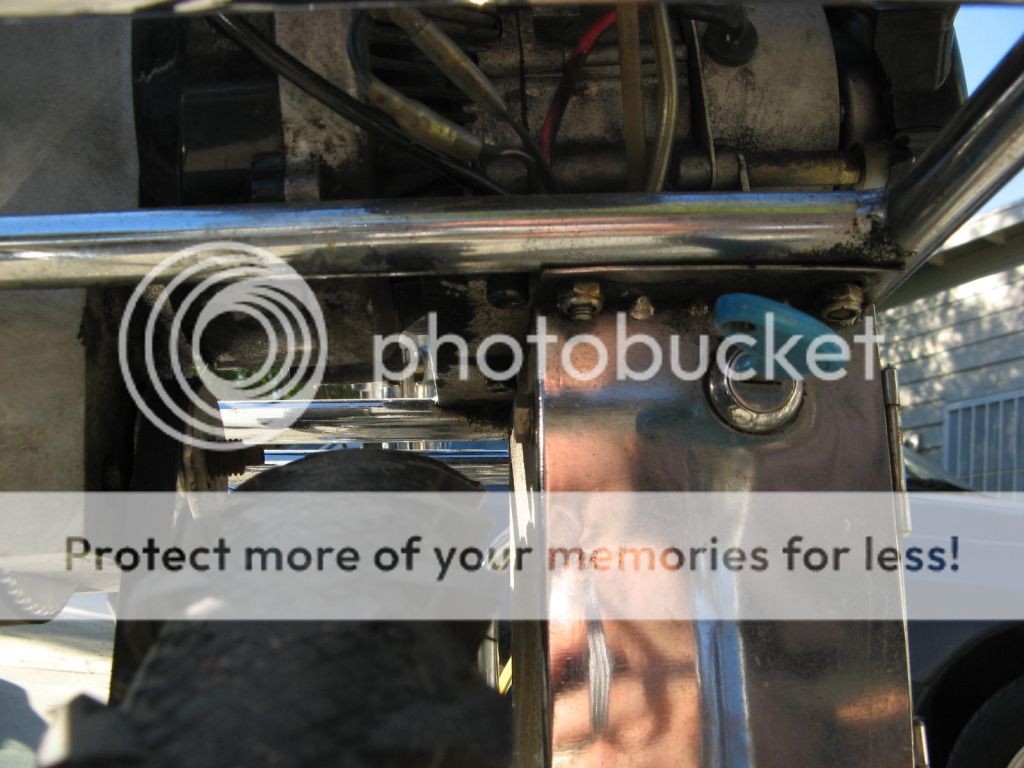

has battery, button start, grip throttle, transmission for nuteral, gas tank

incorporated in the frame. suspension.

Anyhow, the problem is that it has no torque to go up hill....its great going

flat, and some grade, but where I live now...its not cutting it.

can anyone help??

CLICK PICTURES TO MAKE THEM BIGGER IF YOU WISH

CLICK PICTURES TO MAKE THEM BIGGER IF YOU WISH

anyone??? anyone??

has battery, button start, grip throttle, transmission for nuteral, gas tank

incorporated in the frame. suspension.

Anyhow, the problem is that it has no torque to go up hill....its great going

flat, and some grade, but where I live now...its not cutting it.

can anyone help??

CLICK PICTURES TO MAKE THEM BIGGER IF YOU WISH

CLICK PICTURES TO MAKE THEM BIGGER IF YOU WISH