HeadSmess

Well-Known Member

- Local time

- 5:09 AM

- Joined

- May 17, 2010

- Messages

- 3,048

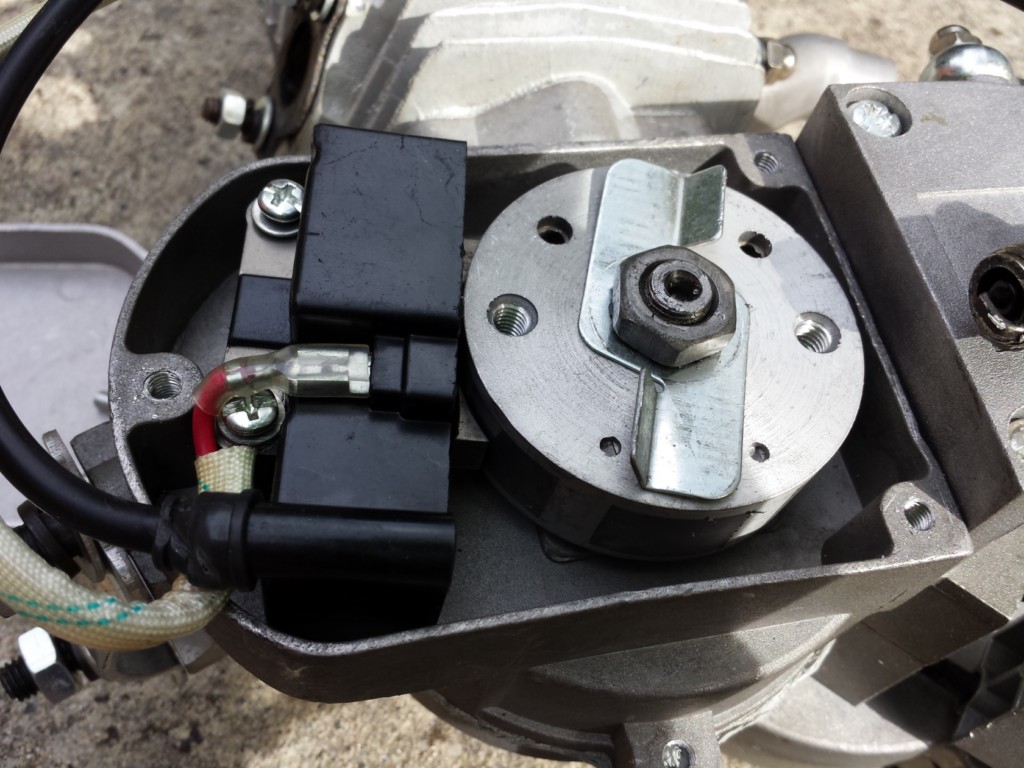

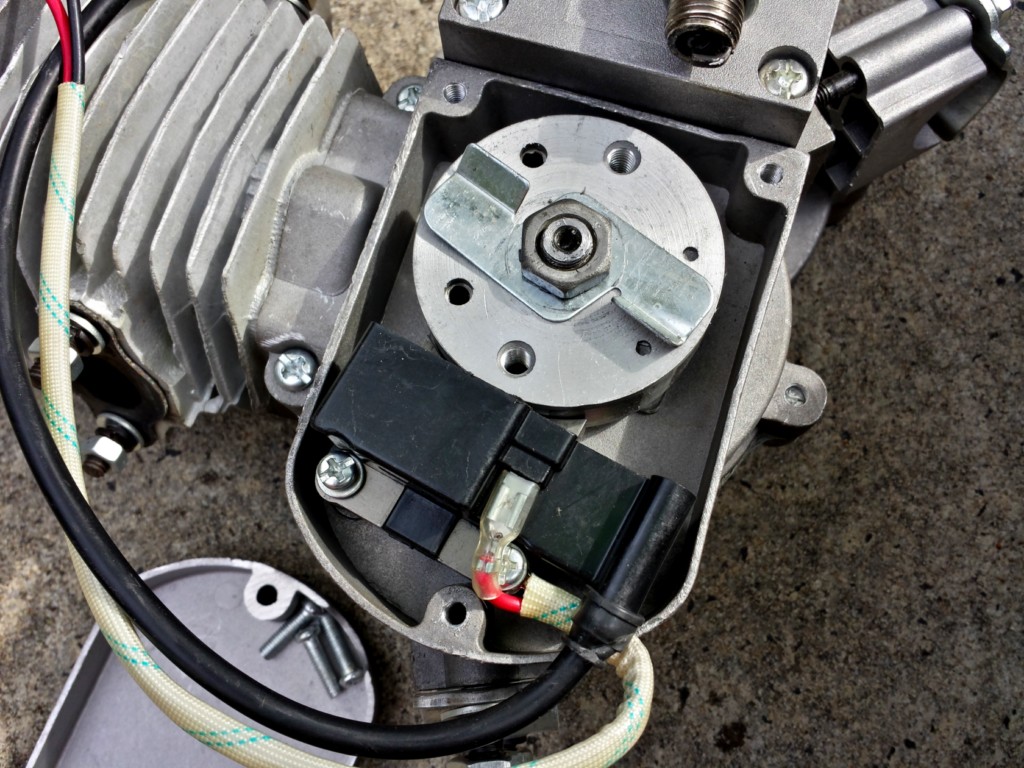

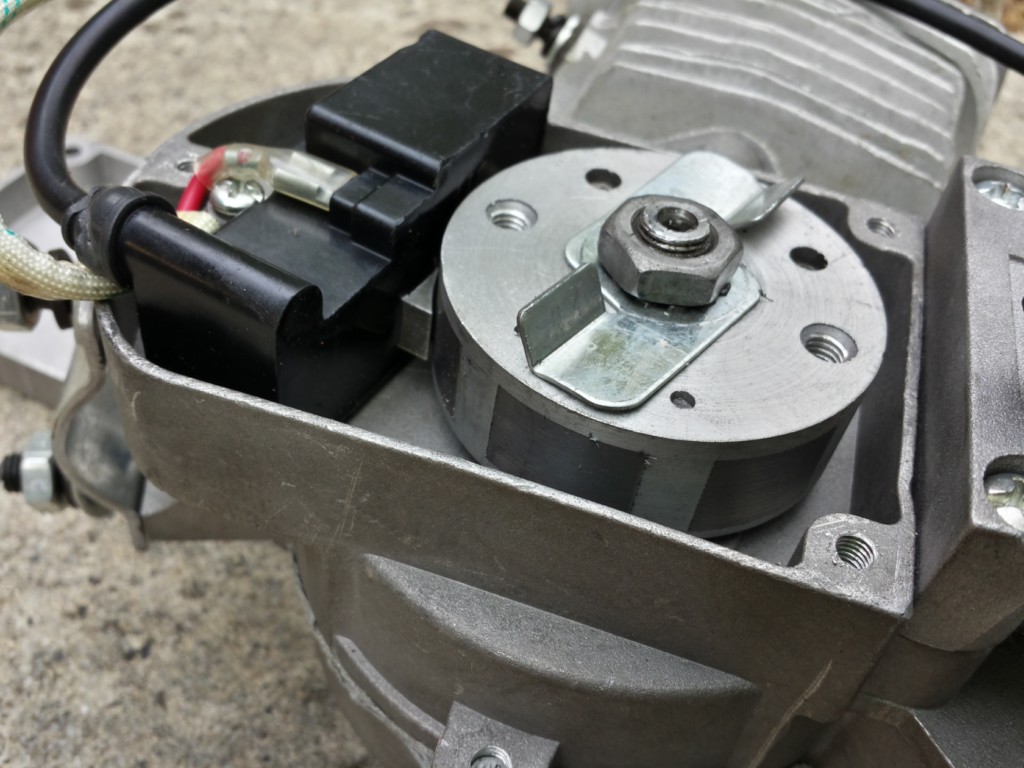

you change the initial advance/retard point by filing the mounting holes. simple.

you change the degree of advance by filing the stator arms at an angle or notching them. simple.

hammers out YOUR conrod bearings.... mine seem to hold up fine at 7000rpm + with standard CDI unit...

at least someone has the capital to invest in some new tooling.maybe some engineer in china just realised that google has a translate function and has started reading?

i dislike the inability to be retrofitted, or maybe they can be?

yes, assuming makes an ass out of you and me...so who will be first out with the timing light and a permanent marker? the answer to how the curve progresses will become apparent in the first five seconds...but then, cant rev it past 5000 rpm now, can we? it might explode... better be careful and put a rev limiter on it, just in case.

more to the point...give us a picture up the exhaust port at BDC.... until that issue is fixed, all "70cc" engines are

you change the degree of advance by filing the stator arms at an angle or notching them. simple.

hammers out YOUR conrod bearings.... mine seem to hold up fine at 7000rpm + with standard CDI unit...

at least someone has the capital to invest in some new tooling.maybe some engineer in china just realised that google has a translate function and has started reading?

i dislike the inability to be retrofitted, or maybe they can be?

yes, assuming makes an ass out of you and me...so who will be first out with the timing light and a permanent marker? the answer to how the curve progresses will become apparent in the first five seconds...but then, cant rev it past 5000 rpm now, can we? it might explode... better be careful and put a rev limiter on it, just in case.

more to the point...give us a picture up the exhaust port at BDC.... until that issue is fixed, all "70cc" engines are