Frankenstein

Deceased - Frankenstein 1991 - 2018

- Local time

- 4:17 AM

- Joined

- Jun 24, 2016

- Messages

- 5,035

We have here a pretty standard centrifugal clutch kit, a few extras as far as grease fittings go. As Fabian knows his China girls and states quite clearly, lubrication is everything.

1: clutch bell and bevel gear : crankshaft collar is currently installed.

2: crankshaft collar

3:bolt that holds the boot assembly and crankshaft collar on crankshaft.

4: This is a heavy bearing that is part of the one-way bearing which allows pedal starts or even kick starts depending on design. It's really heavy duty, it might even mushroom the collar preventing disassembly,luckily it came with a puller tool which is not pictured.

5: this is the retention spring for the one way bearing. It can be installed in several ways but only one spot is effective to keep proper pressure on the bearing, if not under enough pressure it will not work very effectively, and will slip as a pedal start us attempted, more on this later.

6: Various brass fittings and matching taps, will construct better grease application later.

7: simple junk drawer grease applicator in making.

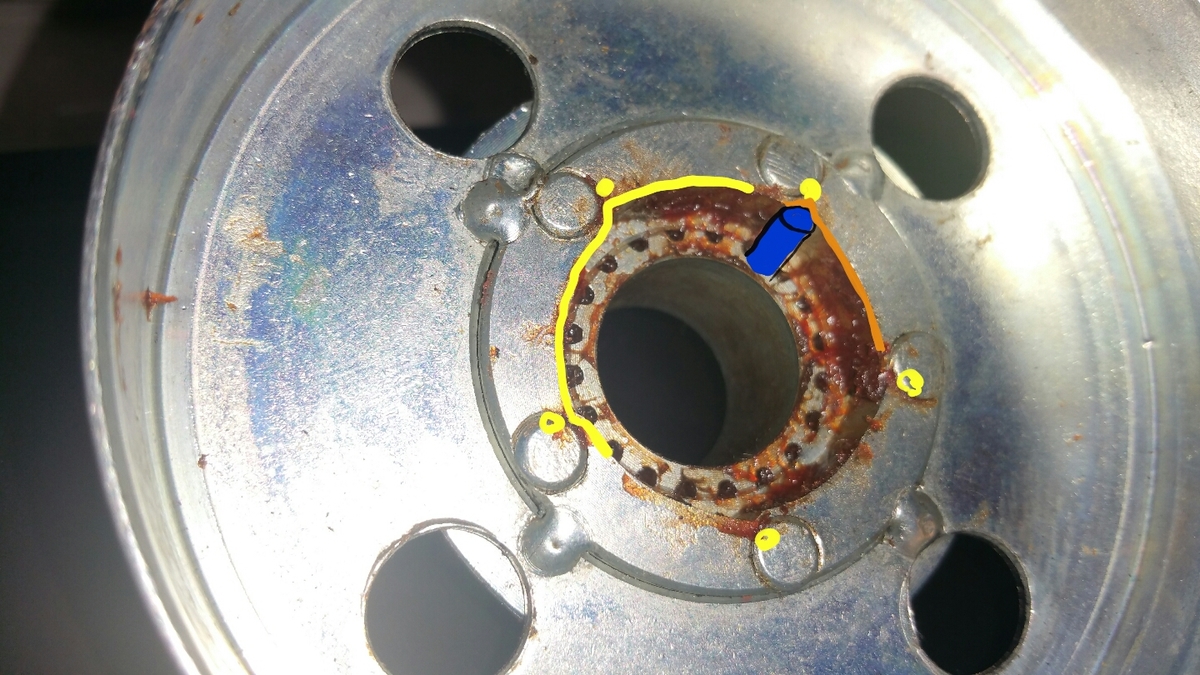

Here's a better look into the bell. The yellow circles indicate where a groove is cut into the metal to act as the float zone for a roller in a one-way bearing.

The blue thing is your imagination making it look like a roller in the groove.

You see all those tiny black/red spots that circle where the gear is pressed in from the other side. Those are open holes, grease can pass right through to the bearings and rolling surface while it's hot and steamy down there and all the hot gears grinding along eachother with all the lube flowing between them. Ahem.. Uh moving on.

Sideways shot where the bearing rests in its grooves.

And here one of it on that shaft. Few more poses for the 3d thinkers.

1: clutch bell and bevel gear : crankshaft collar is currently installed.

2: crankshaft collar

3:bolt that holds the boot assembly and crankshaft collar on crankshaft.

4: This is a heavy bearing that is part of the one-way bearing which allows pedal starts or even kick starts depending on design. It's really heavy duty, it might even mushroom the collar preventing disassembly,luckily it came with a puller tool which is not pictured.

5: this is the retention spring for the one way bearing. It can be installed in several ways but only one spot is effective to keep proper pressure on the bearing, if not under enough pressure it will not work very effectively, and will slip as a pedal start us attempted, more on this later.

6: Various brass fittings and matching taps, will construct better grease application later.

7: simple junk drawer grease applicator in making.

Here's a better look into the bell. The yellow circles indicate where a groove is cut into the metal to act as the float zone for a roller in a one-way bearing.

The blue thing is your imagination making it look like a roller in the groove.

You see all those tiny black/red spots that circle where the gear is pressed in from the other side. Those are open holes, grease can pass right through to the bearings and rolling surface while it's hot and steamy down there and all the hot gears grinding along eachother with all the lube flowing between them. Ahem.. Uh moving on.

Sideways shot where the bearing rests in its grooves.

And here one of it on that shaft. Few more poses for the 3d thinkers.