H

Hive

Guest

ADD EZ INSTALLING HINTS AND RUNNING YOUR BIKES WITH GEBE MOUNT SYSTEM:

Basics (and see also the "sticky" on How GEBE systems work.)

Let's keep it simple suggestions as starters - tell it here!.

GEBE kits allow 100% free wheel pedaling.

Bike having wheel with internal transmission shifter cable entering axle from end will not work. Will have to switch trans or go to coaster only.

Be sure to measure bike correctly - best not to buy bike with incorrect measurements; You need 1.25 inches from closest spoke at point 7.25 inches forward of rear axle - see GEBE site. Guessing seldom works. Ask first.

Thin (700) wheels and road bikes are not really safe or comfortable, though they may be ones you have. You are better off finding a used cruiser or MTB and going from there. Used MTB are all over the place and cheap.

Engines, yours or GEBE are all better off vertical or very close to vertical to max fuel fill.

High horsepower is not a big deal. You do not really want to move a cruiser or MTB faster than 15 - 20 mph; bad for bike, dangerous for you. Engine weight and noise are factors. Need speed, get a different rig.

Be sure Fuel Tube extends all the way to bottom of tank. It is not good for 2-cycles to run dry and you want to use all available fuel. You can find fuel tubes at local mower dealers. Not difficult to remove tank and R & R the tube.

Only start and run engine with drive belt in place, per GEBE.

Run 2-cycles as recommended. Rich break-in formulas are urban myths. Engines are chrome-lined and built to last.

Break-in is 1,500 to 2,000 hours.

Two brakes. Coaster plus or any other sets.

Larger tires , say 2.25 size can cause problem, BUT, you can place SS washers between drive gear and spindle to move belt outward; and move engine around on mount per GEBE site, so belt is not rubbing on drive ring or tire. I ran engine with big Bontragers and no problem, but I guess the rule should be only as wide as practical and that may be limited to 2.00 inches, so extra tweaking is not needed or will downgrade performance. Am using 1.95 Armadillo now and it is perfect. Comfy ride and no adjustments needed. It is also bulletproof.

36-spoke rear wheel is best option and these are available from GEBE, prevents slippage of drive ring more likely with 34 spokes.

High rev starts without pedal assist will also cause spoke problems and slippage, I understand.

Longer axle - 8.5" minimum is recommended, so you may use SS washers between nuts and lock mount to axle mount nut, etc. If you use a 9 incher, maybe ss acorn end nuts will protect the threads best. My 8.5 is nutted to ends.

The main engine axle support can be easily spread and drilled for additional support bars, lights, etc.

The single engine support bar can be any material and can be bent as needed and mounted to seat post, cross bar supports, seat bolts, etc. Normally, the two strips that they supply will cover most applications.

Bolts supplied by GEBE can be replaced with SS.

Rear fender may not have enough clearance under engine with fat tires, and this can sometimes be fixed by drilling hole in fender where nut is located - rare.

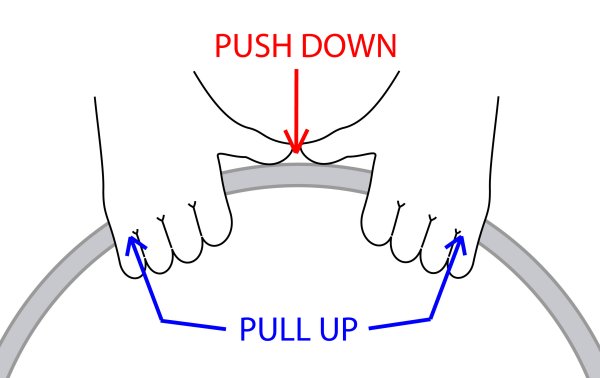

Drive ring is self-centering, if you get the spokes lined up correctly. I used WD-40 (not the spray) to install drive ring and wiped off, but soap needs to be washed off to prevent rust and problems with painted spokes. Need to reduce potential slippage of ring.

Replace throttle and stop button clips with SS hose clamps.

There is site on install on CF bike here: http://www.norcom2000.com/users/dci...cumbent/moto_bike_page/motorized_bicycle.html and another by Lee here: http://lee.org/blog/archives/2005/08/10/motorized-bicycle/. First shows problem solving and logic to compare to your situation and how you might do differently. Second site has loads of links and info. Good stuff to review.

Pedaling bike under power is what lots of people do. Steep hills will often require pedal assist.

Look for separate thread on making throttle cables.

Basics (and see also the "sticky" on How GEBE systems work.)

Let's keep it simple suggestions as starters - tell it here!.

GEBE kits allow 100% free wheel pedaling.

Bike having wheel with internal transmission shifter cable entering axle from end will not work. Will have to switch trans or go to coaster only.

Be sure to measure bike correctly - best not to buy bike with incorrect measurements; You need 1.25 inches from closest spoke at point 7.25 inches forward of rear axle - see GEBE site. Guessing seldom works. Ask first.

Thin (700) wheels and road bikes are not really safe or comfortable, though they may be ones you have. You are better off finding a used cruiser or MTB and going from there. Used MTB are all over the place and cheap.

Engines, yours or GEBE are all better off vertical or very close to vertical to max fuel fill.

High horsepower is not a big deal. You do not really want to move a cruiser or MTB faster than 15 - 20 mph; bad for bike, dangerous for you. Engine weight and noise are factors. Need speed, get a different rig.

Be sure Fuel Tube extends all the way to bottom of tank. It is not good for 2-cycles to run dry and you want to use all available fuel. You can find fuel tubes at local mower dealers. Not difficult to remove tank and R & R the tube.

Only start and run engine with drive belt in place, per GEBE.

Run 2-cycles as recommended. Rich break-in formulas are urban myths. Engines are chrome-lined and built to last.

Break-in is 1,500 to 2,000 hours.

Two brakes. Coaster plus or any other sets.

Larger tires , say 2.25 size can cause problem, BUT, you can place SS washers between drive gear and spindle to move belt outward; and move engine around on mount per GEBE site, so belt is not rubbing on drive ring or tire. I ran engine with big Bontragers and no problem, but I guess the rule should be only as wide as practical and that may be limited to 2.00 inches, so extra tweaking is not needed or will downgrade performance. Am using 1.95 Armadillo now and it is perfect. Comfy ride and no adjustments needed. It is also bulletproof.

36-spoke rear wheel is best option and these are available from GEBE, prevents slippage of drive ring more likely with 34 spokes.

High rev starts without pedal assist will also cause spoke problems and slippage, I understand.

Longer axle - 8.5" minimum is recommended, so you may use SS washers between nuts and lock mount to axle mount nut, etc. If you use a 9 incher, maybe ss acorn end nuts will protect the threads best. My 8.5 is nutted to ends.

The main engine axle support can be easily spread and drilled for additional support bars, lights, etc.

The single engine support bar can be any material and can be bent as needed and mounted to seat post, cross bar supports, seat bolts, etc. Normally, the two strips that they supply will cover most applications.

Bolts supplied by GEBE can be replaced with SS.

Rear fender may not have enough clearance under engine with fat tires, and this can sometimes be fixed by drilling hole in fender where nut is located - rare.

Drive ring is self-centering, if you get the spokes lined up correctly. I used WD-40 (not the spray) to install drive ring and wiped off, but soap needs to be washed off to prevent rust and problems with painted spokes. Need to reduce potential slippage of ring.

Replace throttle and stop button clips with SS hose clamps.

There is site on install on CF bike here: http://www.norcom2000.com/users/dci...cumbent/moto_bike_page/motorized_bicycle.html and another by Lee here: http://lee.org/blog/archives/2005/08/10/motorized-bicycle/. First shows problem solving and logic to compare to your situation and how you might do differently. Second site has loads of links and info. Good stuff to review.

Pedaling bike under power is what lots of people do. Steep hills will often require pedal assist.

Look for separate thread on making throttle cables.