hey all,

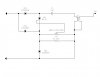

I'm trying to find a decent coil so I can build my own CDI circuit and play around with timing curves and components.

Anyone used this gy6 before? would it work on a skyhawk 2012 with an appropriate CDI?

I've tried the jaguar - prolly just me cause I hear everyone has great results - but my jag CDI lasted about 5 rides before it died - so Im not impressed or going that route anymore - I'm gonna have to build my own I think. Also the jag is built around top speed, not low end torque - and I need that torque to get up hills - so not only the quality issue, but that jag didnt do what I wanted it to. clearly I need to design my own. sorry jag - I really respect your info but it did not work for me.

and yes - I am an electronics guy who designs his own circuits - I figure if I just get the coil I can build my own electronics. So yes, the jag was installed correctly, and had no broken wires.

oh - just noticed jnm has a warranty on that jag cdi - maybe I just got a faulty one?

still want to build my own.

ps - I've built most of the consumer grade electronics in my home - this is basic stuff once I figure out what needs to be done

I'm trying to find a decent coil so I can build my own CDI circuit and play around with timing curves and components.

Anyone used this gy6 before? would it work on a skyhawk 2012 with an appropriate CDI?

I've tried the jaguar - prolly just me cause I hear everyone has great results - but my jag CDI lasted about 5 rides before it died - so Im not impressed or going that route anymore - I'm gonna have to build my own I think. Also the jag is built around top speed, not low end torque - and I need that torque to get up hills - so not only the quality issue, but that jag didnt do what I wanted it to. clearly I need to design my own. sorry jag - I really respect your info but it did not work for me.

and yes - I am an electronics guy who designs his own circuits - I figure if I just get the coil I can build my own electronics. So yes, the jag was installed correctly, and had no broken wires.

oh - just noticed jnm has a warranty on that jag cdi - maybe I just got a faulty one?

still want to build my own.

ps - I've built most of the consumer grade electronics in my home - this is basic stuff once I figure out what needs to be done