dchevygod

Member

- Local time

- 2:39 PM

- Joined

- Mar 7, 2011

- Messages

- 473

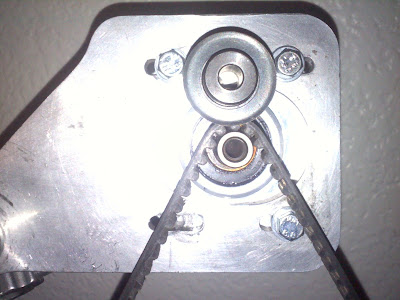

I've seen the 46cc engine used on an MBC but not the 31 or smaller. The 29cc RC motor on ddm makes 3.5 hp @ 14000rpm stock! The 460 is 4.2 hp @ 13000rpm, I'm almost done with a gebe based belt drive for my bike. I used a billet goped motor mount, a FD u bracket, some spacers , gebe belt and sheave and 2 14-15t 5m belt pulleys that just need to be lathed to fit on the clutch from ADA racing I'm using. The mount is really clean looking. I used a turnbuckle to adjust belt tension so ther isn't any side support struts. I need a motor, fuel tank and throttle! My schwinn scooter with a goped engine got stolen and I'm without a ride untill I finish this build. I will get pics asap. Any comments or concerns with using a high output 29cc engine? I'm open for all feedback good or bad.

Last edited: