Hey guys, I'm about to build my first 6.5hp bike. I just wanted to know how to go about welding on the bike tube, what power setting and such. I have a 90amp flux core welder, will it be able to weld the mount plate? thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How do I weld motor mount?

- Thread starter m3h5l5

- Start date

sparky

Active Member

What type of metal is the frame made out of? What type of metal is the mount made out of?

Ideally, you would know the thickness of the tube, and even have a spare tube of the same metal, thickness in order to practice with before actually doing your final run.

Ideally, you would know the thickness of the tube, and even have a spare tube of the same metal, thickness in order to practice with before actually doing your final run.

butre

Well-Known Member

as long as both your frame and the mount are steel, it's all dependent on your skill level.

What both those h iy told u was right on point .let me ask u this though.I ex's there a reason u need to weld a mount...that is a risky and dangerous proposition as far as alignment and getting good penetration and definitely if you do attempt itget something to practice on firstbut I don't recommend ittotally unnecessary

Timbone

Well-Known Member

I would be hesitant to WELD the motor mount onto the thin bike tubing. I would suggest you fab up a custom motormount for the front and rear out of very thick steel that you can attach to the frame via double U-bolts of up to 3/8" steel. You can find thick angle iron and weld your pieces together for both the downtube and the seat tube.

Having a welder is a HUGE advantage. Good luck to you!

Timbone

Having a welder is a HUGE advantage. Good luck to you!

Timbone

fattirejack

Member

I welded my motor mounts on the beast, and an pleased with the results. I have very minimum vibration, the motor is rock solid, and no worries about mounts shifting. Bike frames are made from very thin tubing, and can be different alloys. Your welder should be fine, settings would depend on thickness of your mount material. I welded my 1/4" plate to frame at a setting of 18 amps, but my welder is a high dollar 200 amp welder. If you are using a HF WELDER or similar you may need to set your welder at max to get penetration on your mounts, and take a chance of blowing holes in your frame. PRACTICE ON SCRAP MATERIAL, save yourself frustration, and possibly ruining your frame.

Evil_Genious13

Member

- Local time

- 9:45 PM

- Joined

- Sep 4, 2013

- Messages

- 30

I welded my motor mounts on my motorized bike. the best advice I can give you is do this process with a partner. basically do a mock-up of the rear tire, drive gear, motor and chain, loop the chain over both gears and have a buddy hold the engine to ensure the chain is tight and straight. make sure you tack weld first then double check for chain alignment. if it all looks straight finish your beer and weld it all the way. I use a flux core wirefeed 110v welder.

RumblingV8

Member

I did a decent weld job on my previous bike's motor mount. It's difficult. I didn't realize prior to welding quite how thin my particular bike's frame was and blew a hole in it in the first 1/4" of a pass at the lowest setting... was a little more careful after that and it turned out solid in the end. Next owner messed with the front motor mount and ended up breaking off the mount, probably due to a combination of stress from the changed angle and increased vibration. I elected not to weld the mount on my current bike because the motor fit in the frame properly. I don't think i would weld on a mount again after seeing how solid the U clamp brackets are, I'd rather just fab up a plate for that style mount.

Jeffrey gagnon

Member

- Local time

- 8:45 PM

- Joined

- Apr 29, 2016

- Messages

- 91

I know this is a year late but i have a bike build and im in the planning stage i dont expect to be able to do anything untill next riding season but anyways so here it is it would be this bike

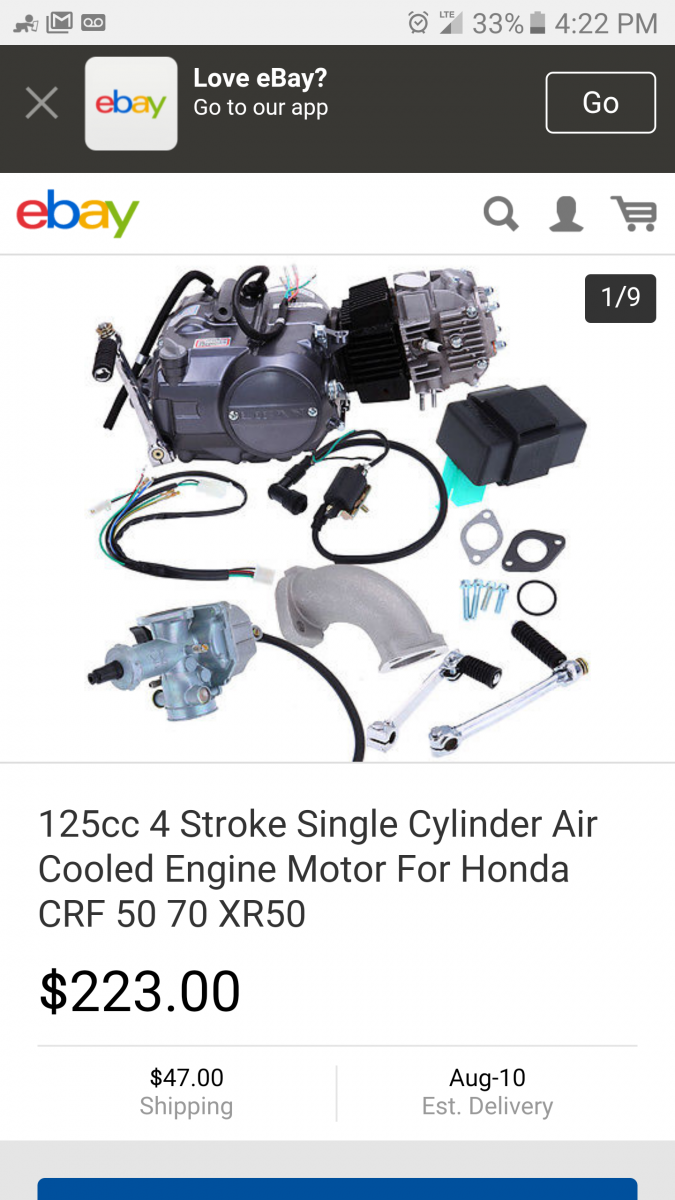

With this motor

So my ideal because im pretty sure this is going to require some fabrication for motor mounts and such i dont have a welder at home but my dad does at his work. so honestly i dont know where to begin on this build i know the mounting methods are much different then our little 66cc engines but i know it can be done ive seen videos on youtube of same engine but on smaller bike then one that i picked out.

The other thing is does anyone know if the lifan 125cc engine can be jackshafted to rear derailleur or might that be too much ideal i was thinking 11 speed moped with this ideal 4 internal 7 external i just want to know if it can be done maybe i fab a homemade heavy-duty derailleur to handle the torque of the engine would this ideal even be worth the thought the ideal behind this was to keep the rear disk brakes or ive heard of an adapter the supposed to work with disk brakes but does that still apply with a 4 inch fat tire bike also from what ive read about Jackshaft kits is its not so much for top speed its more for keeping the engine in the proper rpm range "sweet spot" as well as it helps for the dependability and reliability of the engine

I also plan on adding

Comes with everything headlight high/low, tail lights/running lights, brake, and both front and rear turn signals also includes a 100 decibel horn that can be heard 200 feet away includes battery

So honest feedback from all like i said im going for costom motoped and do plan on registering with the state and get platted and insurance.

With this motor

So my ideal because im pretty sure this is going to require some fabrication for motor mounts and such i dont have a welder at home but my dad does at his work. so honestly i dont know where to begin on this build i know the mounting methods are much different then our little 66cc engines but i know it can be done ive seen videos on youtube of same engine but on smaller bike then one that i picked out.

The other thing is does anyone know if the lifan 125cc engine can be jackshafted to rear derailleur or might that be too much ideal i was thinking 11 speed moped with this ideal 4 internal 7 external i just want to know if it can be done maybe i fab a homemade heavy-duty derailleur to handle the torque of the engine would this ideal even be worth the thought the ideal behind this was to keep the rear disk brakes or ive heard of an adapter the supposed to work with disk brakes but does that still apply with a 4 inch fat tire bike also from what ive read about Jackshaft kits is its not so much for top speed its more for keeping the engine in the proper rpm range "sweet spot" as well as it helps for the dependability and reliability of the engine

I also plan on adding

Comes with everything headlight high/low, tail lights/running lights, brake, and both front and rear turn signals also includes a 100 decibel horn that can be heard 200 feet away includes battery

So honest feedback from all like i said im going for costom motoped and do plan on registering with the state and get platted and insurance.

Frankenstein

Deceased - Frankenstein 1991 - 2018

- Local time

- 9:45 PM

- Joined

- Jun 24, 2016

- Messages

- 5,035

Too f***ing cool! Now I'm wondering... I've been looking at various 4 strokes and been thinking about what I could put in a schwinn Stingray, biggest possible that is.. Only think about a jackshafting this motor is its got a 4 speed transmission which also appears to be a manual shift. That means you'd have a 28 speed transmission, not 11,as you multiply the gears not add them up.

Then the only other thing I could mention is that that much horsepower on a chain designed for a 7 speed cassette would be taking one hell of a beating, along with the rest of the bicycle's drivetrain.

Perhaps you could look into a direct drive system, or an internal hub gear system like a cvt hub from nuvinci. However most gear systems will have issues with anything that's pumping out almost or beyond 11hp...

Cool bike btw, what's it called?

Then the only other thing I could mention is that that much horsepower on a chain designed for a 7 speed cassette would be taking one hell of a beating, along with the rest of the bicycle's drivetrain.

Perhaps you could look into a direct drive system, or an internal hub gear system like a cvt hub from nuvinci. However most gear systems will have issues with anything that's pumping out almost or beyond 11hp...

Cool bike btw, what's it called?

Similar threads

- Replies

- 7

- Views

- 775

- Replies

- 7

- Views

- 355

- Replies

- 76

- Views

- 3K

D