Today, I returned home and for the first time, mounted my Flying Horse 66cc engine and I am very disappointed with how un-level the carb. is. The rear mount is solidly mounted and the engine is as low in the rear as possible (very near the chain guard) so, I'm not sure how to correct the tilting problem??

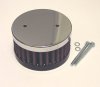

Add to that, the carb. is too close, and even under the horizontal tube, a full 1/2".. making the high performance air filter impossible to use.

I'm happy with everything else. I'm just not sure how to correct the tilted carb?

I wonder if I'm just overlooking something?

Any solutions would be greatly appreciated...

Add to that, the carb. is too close, and even under the horizontal tube, a full 1/2".. making the high performance air filter impossible to use.

I'm happy with everything else. I'm just not sure how to correct the tilted carb?

I wonder if I'm just overlooking something?

Any solutions would be greatly appreciated...