Fabian

Well-Known Member

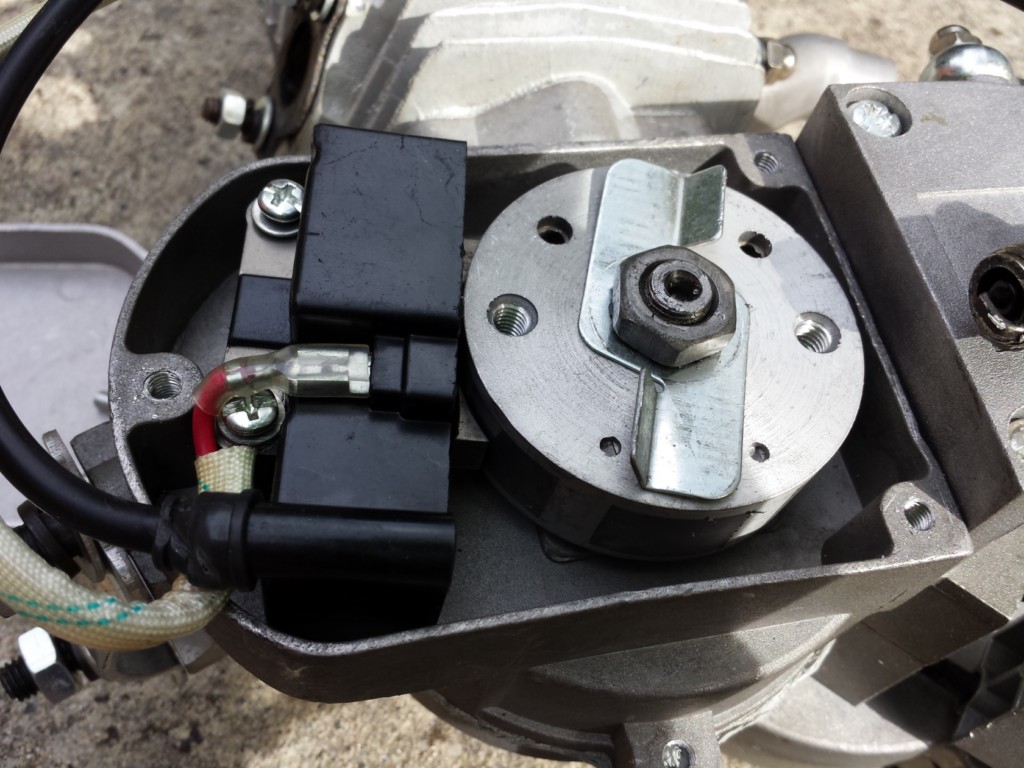

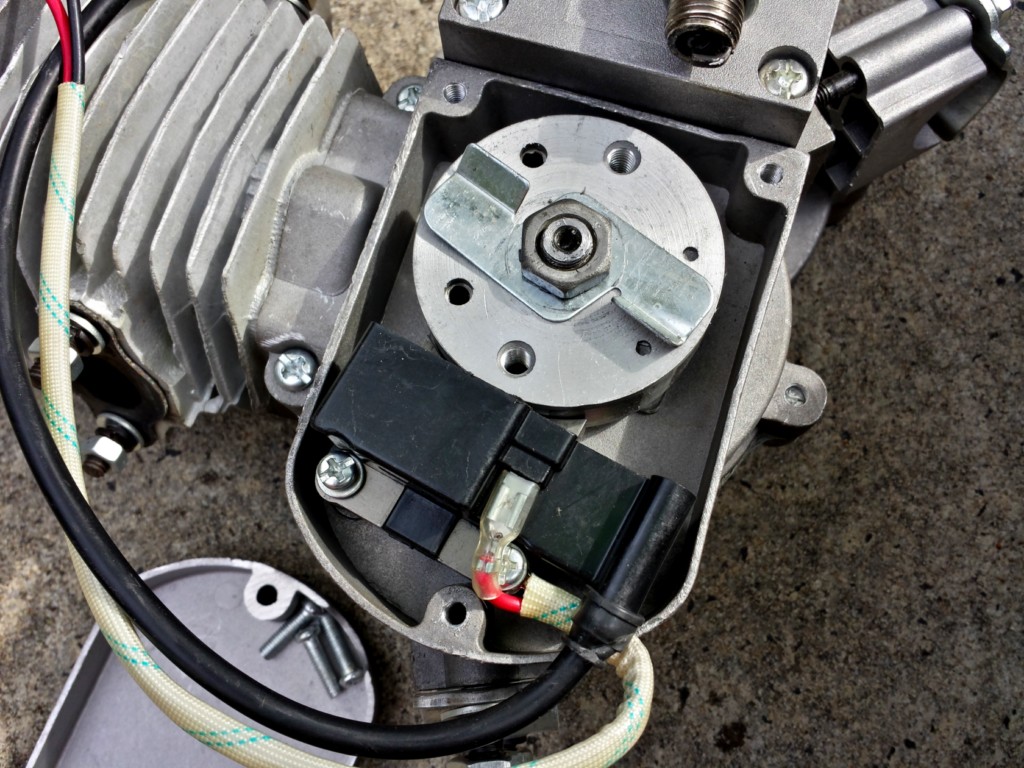

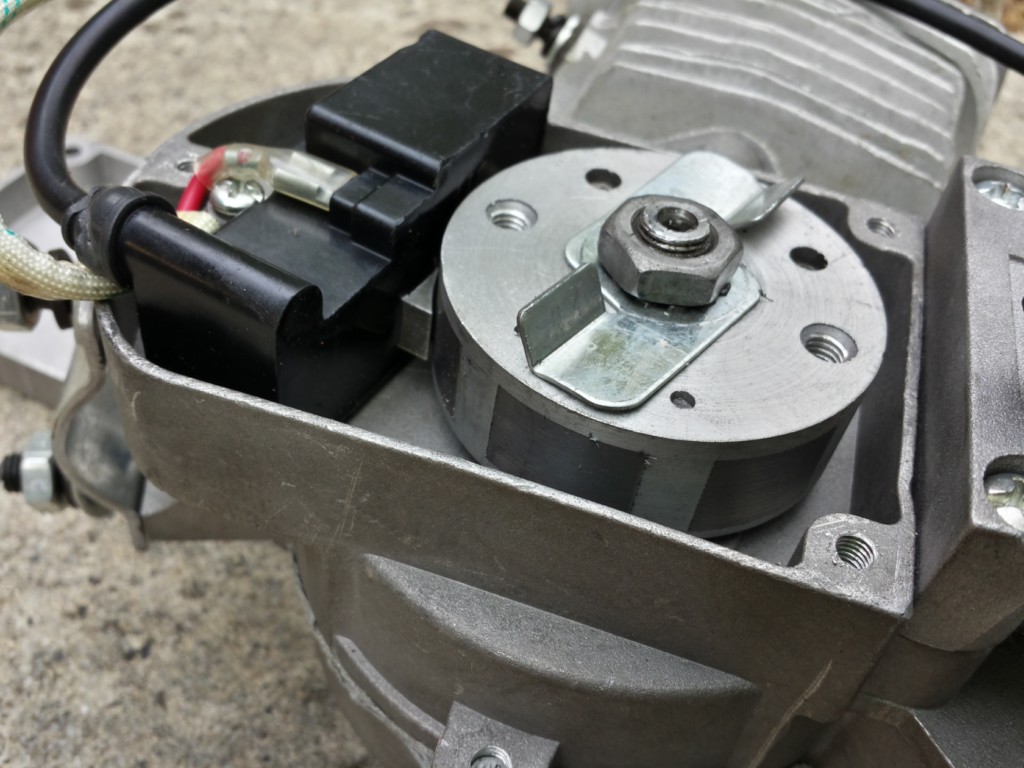

My engine supplier has just got his hands on a 66cc sample engine for me to test; using the new magneto design.

If i find that it's reliable and operates with similar efficiency as the current magneto/coil design, he will order a container shipment.

The engine is similar if not identical to a Grubee Skyhawk "SuperRat", in that it uses an identical 47mm bore, though the stroke is 38mm instead of the "SuperRat" 40mm stroke, which makes the "Rat" engine 69cc; an extra 3cc over the engine i have received.

Here is the engine on the Grubee webpage: http://www.grubeeinc.com/USA/SkyHawk%20Gt5-SR%20SuperRat.html

Having said that, the normal 70cc engines he sells use a 40mm stroke, so if the crankshafts are the same between the new engine design and the old engine design, it would seen logical that the longer stroke crankshaft could be retrofitted into the new engine design.

Thankfully this new engine design is now being sold in the mass market; making magneto parts readily available; Gasbike being one of the suppliers: http://www.gasbike.net/grubee-skyhawk-gt5-sr-66cc-80cc-slant-head-standard-finish-bike-motor-kit.html

The next question directed at my bicycle engine kit supplier was of the ignition advance curve: was it a 4-stroke advance curve like the commonly available magneto/CDI or a proper 2-stroke ignition advance curve.

It turned out that he was unable to give me an answer so i had to do some more digging, hence i went to town on Google.

Doing some research revealed that this particular integrated magneto system is used on the 2-stroke 3WF18 misting blower,

http://www.delshine-garden.com/pid12366891/3WF18-9+(20L)+131kw+Agricultural+Power+Sprayer.htm

http://www.alibaba.com/product-detail/coil-and-rotor-for-WFB-18_307572702.html

and

the company that manufacturers the integrated magneto is Zhongci, which lists the part number as ZC6002, so spare parts supply is not a problem,

http://www.cnzhongci.com/ENGLISH/productshow.asp?id=1198

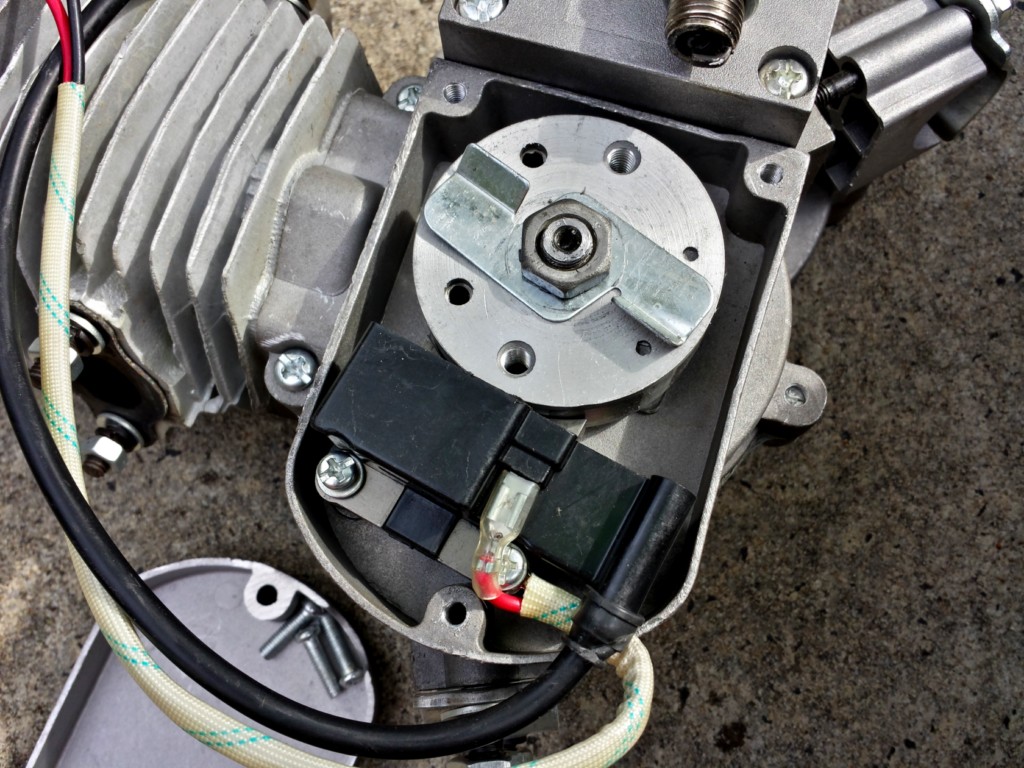

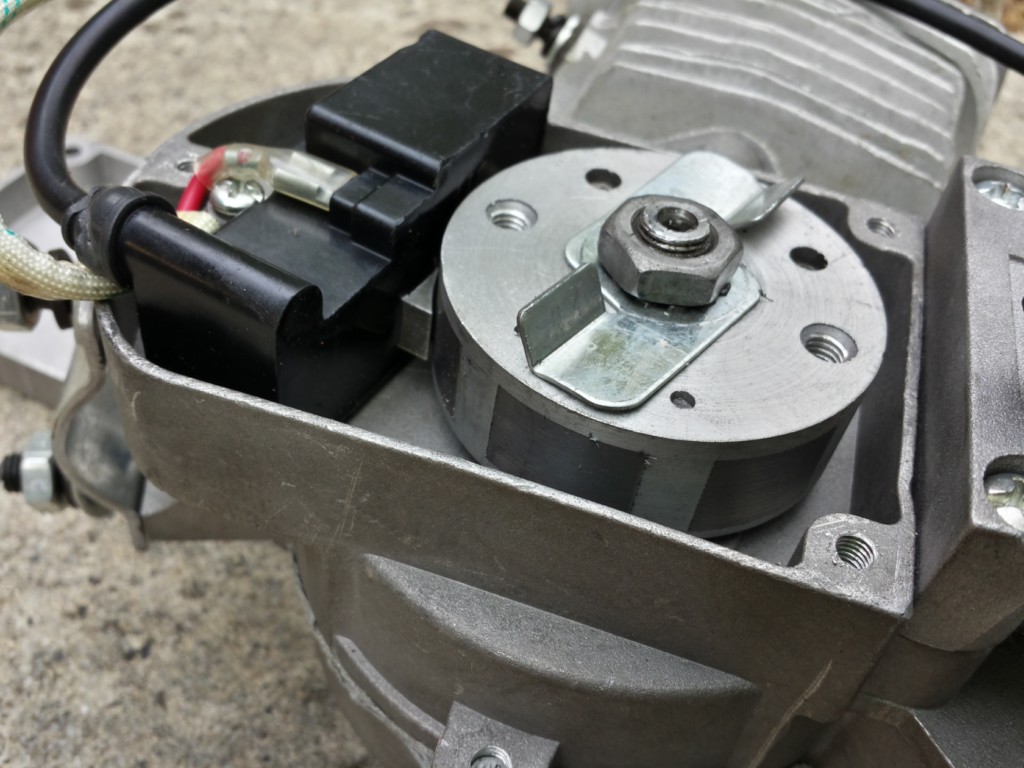

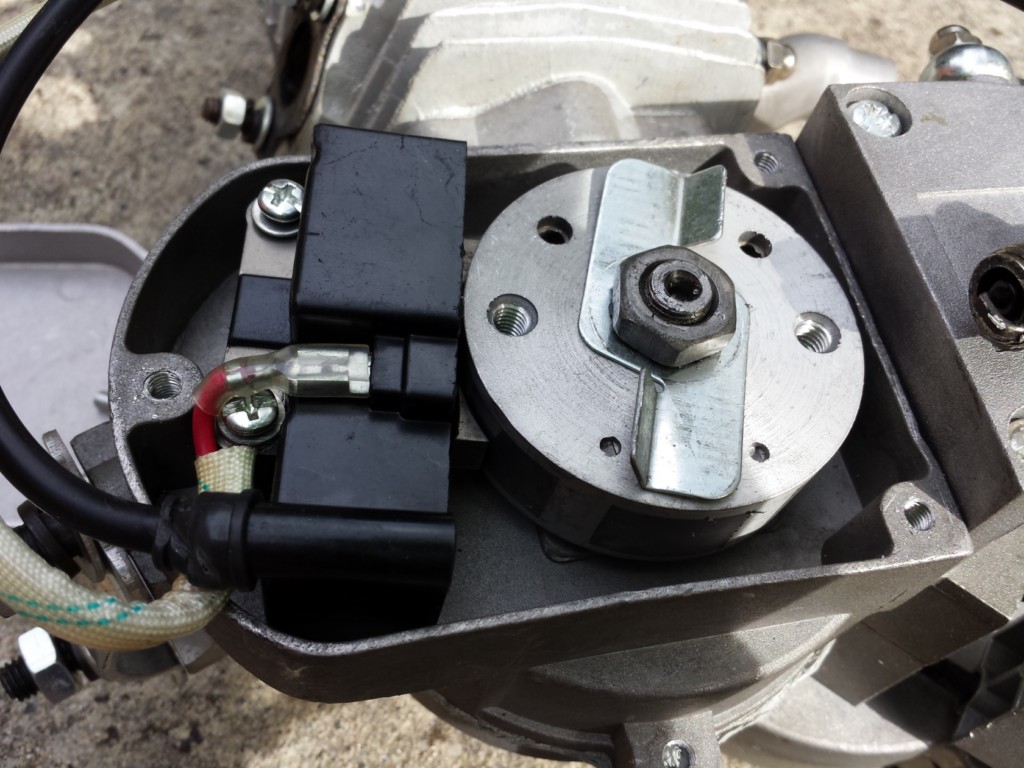

so, without further ado, here are the photos,

A side note is that a small flywheel puller will be needed to remove this type of magnet from the crankshaft:

If i find that it's reliable and operates with similar efficiency as the current magneto/coil design, he will order a container shipment.

The engine is similar if not identical to a Grubee Skyhawk "SuperRat", in that it uses an identical 47mm bore, though the stroke is 38mm instead of the "SuperRat" 40mm stroke, which makes the "Rat" engine 69cc; an extra 3cc over the engine i have received.

Here is the engine on the Grubee webpage: http://www.grubeeinc.com/USA/SkyHawk%20Gt5-SR%20SuperRat.html

Having said that, the normal 70cc engines he sells use a 40mm stroke, so if the crankshafts are the same between the new engine design and the old engine design, it would seen logical that the longer stroke crankshaft could be retrofitted into the new engine design.

Thankfully this new engine design is now being sold in the mass market; making magneto parts readily available; Gasbike being one of the suppliers: http://www.gasbike.net/grubee-skyhawk-gt5-sr-66cc-80cc-slant-head-standard-finish-bike-motor-kit.html

The next question directed at my bicycle engine kit supplier was of the ignition advance curve: was it a 4-stroke advance curve like the commonly available magneto/CDI or a proper 2-stroke ignition advance curve.

It turned out that he was unable to give me an answer so i had to do some more digging, hence i went to town on Google.

Doing some research revealed that this particular integrated magneto system is used on the 2-stroke 3WF18 misting blower,

http://www.delshine-garden.com/pid12366891/3WF18-9+(20L)+131kw+Agricultural+Power+Sprayer.htm

http://www.alibaba.com/product-detail/coil-and-rotor-for-WFB-18_307572702.html

and

the company that manufacturers the integrated magneto is Zhongci, which lists the part number as ZC6002, so spare parts supply is not a problem,

http://www.cnzhongci.com/ENGLISH/productshow.asp?id=1198

so, without further ado, here are the photos,

A side note is that a small flywheel puller will be needed to remove this type of magnet from the crankshaft:

Last edited: