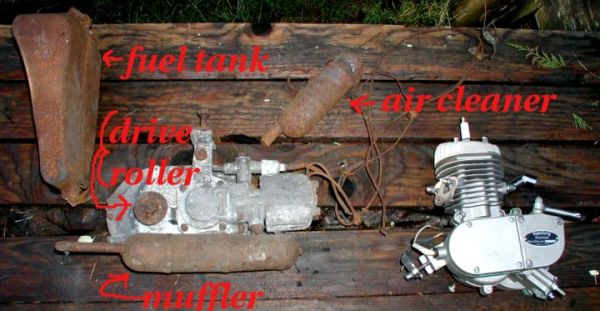

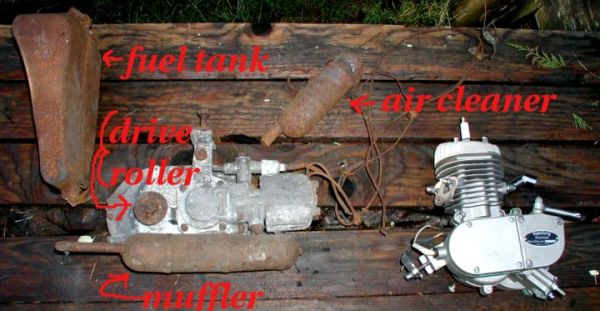

My lohmann nolonger runs. It was in perfect running condition on a beautiful old bicycle. I have good memories of riding with it running . I put this combo together in 1982. It was very low powered, wouldn't push me up a hill without help. I really liked it being sort of a diesel. I stored it in a friend's barn. While I was on a year long trip, the barn burned down and melted alloy parts off the motor and ruined the antique bicycle it was mounted on. I kept the remains hoping to someday find replacement parts. No luck sofar. I had an ownersmanual as well, it totally burned up in the fire. The bicycle was british racing green, with a Hong Kong Bicycle co. decal, a front hub generator, rod brakes, and a 3speed rear hub with a coaster brake, 28X1 1/2 inch wheels, comfy leather saddle and a locking front fork. I bought this bicycle from a man who at one time had been the British Consulate to Hong Kong. He only rode the bike 3 times because he said that Hong Kong was too hilly. It was really very heavy for the little Lohmann to push.