It sounds like you need to adjust your clutch.

When you squeeze in the clutch handle is there any resistance?

In the pic, your clutch cable looks way too loose and it looks like there's slack in it.

If the engine starts and runs but will not idle, turn the idle screw in(the screw in the left side of the carb.).

When you put the slide back in the carb, make sure the short slot goes to the left side, and the long slot (shown in pic #1) goes to the right side and lines up with a little pin that's cast into the inside of the carb.

You should spend some more time on the details and don't rush the build. Whenever you rush, you miss things, and the bike ends up looking like it was thrown together in a few hours and can be unsafe.

Seriously, you need to mount the gas tank to the frame better, and solidy (it can be done with a little inginuity),

You should run your wiring so that it's out of the way and secured to the frame.

Get rid of the stock push together wire connectors and solder all of your wire connections, and then cover them with heat shrink.

That speedo that you have on there won't last but a few days because the internals are all plastic. They will destroy themselves after awhile because they were not meant to go 30 mph.

I know because I had one of those speedos, and it blew apart after about 3 days of riding.

You need to get an in line fuel filter put on there for sure.

That stock chain tensioner probably won't last very long, and it may even end up in the spokes.(it's happened several times).

If you slow down and put some thought into what you're doing you could end up with a really nice looking and great running bike.

the devil is in the details...take your time.

Here's my 2 bikes.

I have about 4 days worth of work just putting the engine on, doing the wiring and making a few custom parts to replace a few kit supplied part for the chopper.

I have about 20 hours in the gas tank (body work and paint) and i have another couple of hours in the exhaust, and tuning the carb. a few misc. hours in making the headlight, the tail light, chopping the seat post and welding a smaller seat post inside of the original one to fit a standard seat on it.

look close...do you see a mount for the gas tank? it's hidden and it cost me about 50 cents to make it.

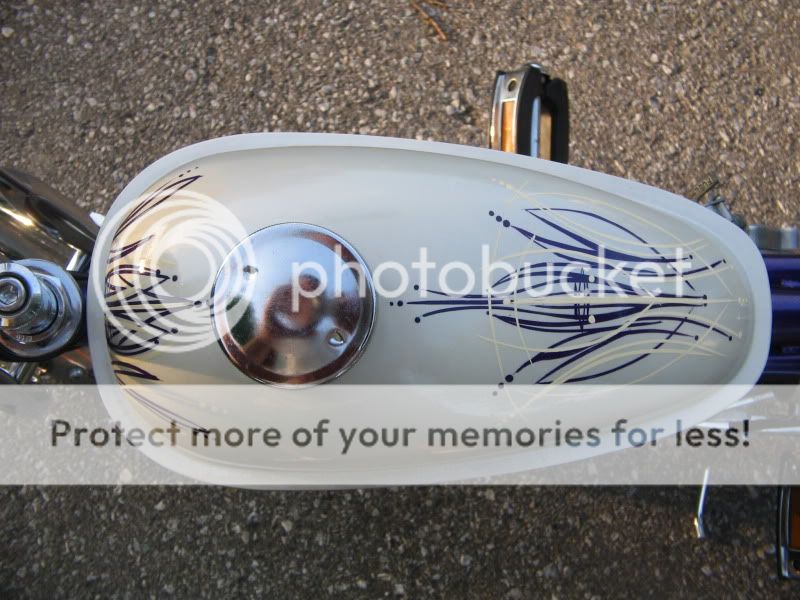

close up of the paint on the tank.

I have about 4 days worth of just putting the engine on and doing the wiring on my lowrider.

I have about 30 hours in the frame (stripping the old paint, repainting it and buffing it out). another couple of hours putting on the expansion chamber and making the custom baffle and exhaust. about an hour in making the custom chain tensioner. and then there's the misc. time i have in chopping the sissy bar(it has shocks on it), chopping both fenders, chopping the seat post, making the headlight and the tail light.

About 15 hours in the gas tank (the pearl white paint job, my friend did the pinstriping.)