FurryOnTheInside

In Memoriam

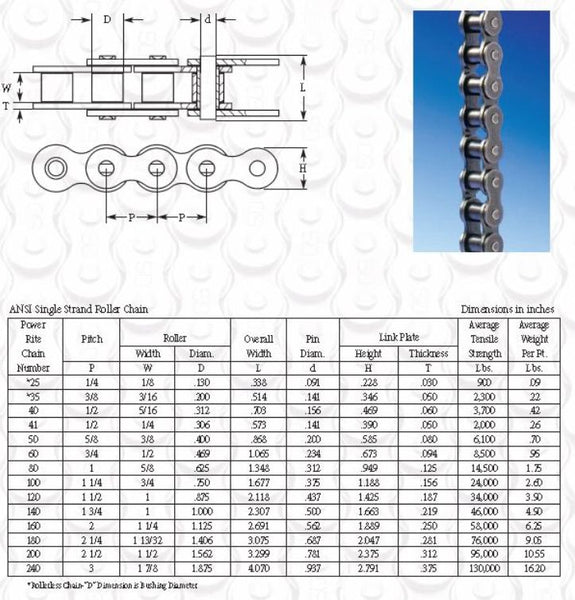

I'm just wondering if anyone has any idea how much load is the chain carrying on a standard 10/44 kit setup.

I have been looking for comparisons between the different standard chain sizes and finding only comparisons of the same size but different brands (those seem to differ far more by wear rate than BS), however the one chart I found showing different sizes of the same brand showed that their (DID) chains have the same average breaking strain (BS) no matter what size (1/8" or 3/16") except their "track racing" 1/8" which I am assuming has thicker side plates, possibly better material.

I am just trying to figure out what the lightest, narrowest chain is that would work (if the sprockets were narrow enough to match).

So yeah, in short what is the minimum BS necessary for direct drive motor chain?

I have been looking for comparisons between the different standard chain sizes and finding only comparisons of the same size but different brands (those seem to differ far more by wear rate than BS), however the one chart I found showing different sizes of the same brand showed that their (DID) chains have the same average breaking strain (BS) no matter what size (1/8" or 3/16") except their "track racing" 1/8" which I am assuming has thicker side plates, possibly better material.

I am just trying to figure out what the lightest, narrowest chain is that would work (if the sprockets were narrow enough to match).

So yeah, in short what is the minimum BS necessary for direct drive motor chain?