D

Deleted member 12676

Guest

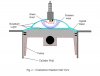

High compression heads are made with an additional feature which allows a minimal squished area between the piston and the head around the periphery of the piston which keeps the piston cooler at top RPM for less possibility of seizing and less possibility of detonation (which eats away at pistons). It is the increased compression which is responsible for most of the power increase, not the squish band. Modifying an engine without a squish band to having one is is a technical venture that has to be done right or else the engine will lose power. Most of the high compression heads with a squish band are made for engines whose cylinder height is equal to the height of the piston edge when it's at the top of its stroke. The GT-5 engine is not one of those engines. If the cylinder is higher than the piston then that allows extra space at piston-top-dead-center (TDC) that hides the fuel mixture that's there from the main combustion area at the critical beginning of the flame creation (from 10 degrees before TDC to 10 degrees after). So if 20% of the mixture is in that excessive squish area then its like having reduced your engine size by 20%. If your piston is lower than the cylinder top (at TDC) then you have to take it to a machine shop to have it lathed down that same distance. Unfortunately this info is mostly sidestepped by the sellers of these heads. What is the right squish clearance (between piston and head)? It is .012" to .024" (.3 to .6mm) for these small engines. (Less than .3mm allows the piston to hit the head when the engine gets hot due to lengthening of the connecting rod due to heat.)

Here's how to measure it:

Buy solder from Radio Shack. take off the head. position the piston so that when you push the bike it will rise. set it just a bit down (before TDC). put a length of solder on top of the piston from the left side to the right side. put the head back on and then push the bike. if you feel no resistance from the engine having to squish the solder then your squish clearance is ridiculously too much. try not to turn the engine over much past the TDC point. that gives less chance for the solder to fall into a port. take the head off and use a dial caliper (#142 $24 in Home Depot) to measure the squished thickness of the solder. that thickness is the squish clearance. If it isn't squished then coil two strands of solder together to make it twice as thick and retest. If it's more than .6mm and the cylinder is flush with the piston top then you can plane down the head by using sandpaper on thick glass.

Here are the sellers, their high compression heads, and what they do or don't say about the squish band. None of them fully explain like I have here:

Bicycle Motor Works

6.0cc High Compression Billet Aluminum Head

"Deck height of zero to .03″ (.8mm) [needed] for maximum compression. NOTE: GT-5 engines have a higher deck than most others. You will need to bring the deck height down to fully appreciate added power."

CRMachine

Stage 2 [6.0cc]Cylinder Head 66/80cc:

"Please be aware that in order gain the maximum benefit from this cylinder head, you will need to bring the outer edge of the piston to (or close to) the top of the cylinder. A close "squish" clearance has better combustion efficiency. If you have a GT-5 engine, using a shortened cylinder body will produce optimal results. Check out our cylinder bodies and complete top end kits for the GT-5 engine."

Jake's

Billet High Compression "Diamond Head"

"Squish-band design seats the head perfectly into the cylinder, funneling

gasses precisely to the combustion point at the spark plug, increasing

efficiency and reducing potential detonation; a condition where hot

spots in the engine cause the fuel to combust in unwanted areas such as

under the piston, or at various undesirable points inside the chamber. "

KingsMotorBikes

High Compression Cylinder Head 80cc 60cc

"This cylinder head incorporates a squish band which has been proven to allow increased compression while reducing the risk of detonation. Please be aware that in order gain the maximum benefit from this cylinder head, you will need to bring the outer edge of the piston to (or close to) the top of the cylinder.

*The GT-5 engine has a different crankshaft assembly and piston than most other engines, and has low compression. Adjusting the compression by decking the cylinder jug is necessary for the GT-5 engine in order to gain proper compression ratio."

Arrow Motorized Cycles

Stock Rechambered Cylinder Heads

[nothing said]

Rock Solid Engines

Billet 70cc Cylinder Head

[nothing said]

PedalChopper

"HEMI- SPHERICAL" HIGH COMPRESSION HEAD

[nothing said]

GasBike

Racing CNC Cylinder Head 66cc / 80cc

[nothing said]

Last edited by a moderator: