HeadSmess

Well-Known Member

- Local time

- 9:35 AM

- Joined

- May 17, 2010

- Messages

- 3,048

i finally pulled apart my old magneto that burnt out, in the hope that i can rewind it.

carefully pulled the core apart. just drill...five rivets. four are alloy.

carefully remove former. note direction of winding, and start unwrapping.

turn 1066, and theres the burnt out section!

3500 in total. (i have a coil winder. cant do transformers without one!)

and here is where it gets weird.

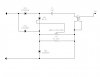

its always been assumed that the little "earth" tap, the dodgy solder join, is a tap, with both coils common to it, the other ends going to blue and white respectively.

apparently not.

the blue wire unwraps CCW, and is joined to the white wire! then the white wire continues unwrapping CCW, in a heavier guage, terminating at the earth/solder join.

(this is a "new" old magneto, the version where they have the date...5.11.2011 i think mine was... nicely made ones)

this means that...

you should be able to wire the cdi with blue/blue, black/white! with killswitch shorting these as per normal(ish)!

then the "earth" or frame is "isolated" and white is then available for power in a single wire "chassis is earth" setup! ie, a direct replacement for a dynamo. (its technically what that winding is. a dynamo.)

WITHOUT BURNING OUT OR DYING OR LOADING THE SYSTEM UNDULY.

shame i dont have a working magneto to test this theory out on.

if they are ALL wired like this, then it explains exactly why they burn out with monotonous regularity!!!!!

because black is earth, or so we think, we normally wire this to the cdi, so there is the power coils voltage ADDED to the CDI voltage.

shorting the white wire to earth should still keep the cdi operating, but the shorted power coil overloads the system, therefore acting as a killswitch. that was always a sure fire magneto killer.

adding any load to the power winding affects the trigger voltage/current to the cdi, as its reference is "floating" in regards to earth. affects the timing AND charge voltage/current. too much load and theres no charge voltage left over.

im also thinking this extra voltage is changing the advance curve? especially if the power winding is for some reason backwards, which would subtract from the trigger voltage...

the newer black/blue only coils do run better...

theres also back EMF to consider. collapsing magnetic fields and all that.

anyways. im going to rewind this thing with two coils side by side, with a definite ground tap and seperate cdi wires. use slightly heavier wire on the ignition. and double turns on power for 12v!

what is weird is i did have a magneto that powered an LED light fine... not this one. obviously there are some variations in winding!

im pretty sure that on the real old ones there was a fine wire soldered externally with the heavy one...

i shall be pulling more of these apart now

carefully pulled the core apart. just drill...five rivets. four are alloy.

carefully remove former. note direction of winding, and start unwrapping.

turn 1066, and theres the burnt out section!

3500 in total. (i have a coil winder. cant do transformers without one!)

and here is where it gets weird.

its always been assumed that the little "earth" tap, the dodgy solder join, is a tap, with both coils common to it, the other ends going to blue and white respectively.

apparently not.

the blue wire unwraps CCW, and is joined to the white wire! then the white wire continues unwrapping CCW, in a heavier guage, terminating at the earth/solder join.

(this is a "new" old magneto, the version where they have the date...5.11.2011 i think mine was... nicely made ones)

this means that...

you should be able to wire the cdi with blue/blue, black/white! with killswitch shorting these as per normal(ish)!

then the "earth" or frame is "isolated" and white is then available for power in a single wire "chassis is earth" setup! ie, a direct replacement for a dynamo. (its technically what that winding is. a dynamo.)

WITHOUT BURNING OUT OR DYING OR LOADING THE SYSTEM UNDULY.

shame i dont have a working magneto to test this theory out on.

if they are ALL wired like this, then it explains exactly why they burn out with monotonous regularity!!!!!

because black is earth, or so we think, we normally wire this to the cdi, so there is the power coils voltage ADDED to the CDI voltage.

shorting the white wire to earth should still keep the cdi operating, but the shorted power coil overloads the system, therefore acting as a killswitch. that was always a sure fire magneto killer.

adding any load to the power winding affects the trigger voltage/current to the cdi, as its reference is "floating" in regards to earth. affects the timing AND charge voltage/current. too much load and theres no charge voltage left over.

im also thinking this extra voltage is changing the advance curve? especially if the power winding is for some reason backwards, which would subtract from the trigger voltage...

the newer black/blue only coils do run better...

theres also back EMF to consider. collapsing magnetic fields and all that.

anyways. im going to rewind this thing with two coils side by side, with a definite ground tap and seperate cdi wires. use slightly heavier wire on the ignition. and double turns on power for 12v!

what is weird is i did have a magneto that powered an LED light fine... not this one. obviously there are some variations in winding!

im pretty sure that on the real old ones there was a fine wire soldered externally with the heavy one...

i shall be pulling more of these apart now

Last edited: