YetiWoodz

Well-Known Member

You don't need to buy a truing stand. Make your own like I did.

Making A Truing Stand

Just take any old bicycle fork and jb weld 2 nuts on it and put matching bolts through it. Cap off the ends with something that won't scratch your rim. I used tire valve caps which actually threaded right on to the bolts. Then make, buy, or use any kind of stand to put it on. I used my bicycle stand. Now its a 2 in one stand lol.

Fixing Flat Spots

Next, buy a spoke tool if you don't have one. You can get 2 for $6 on amazon. It tightens/loosens spokes of any size.

Amazon link

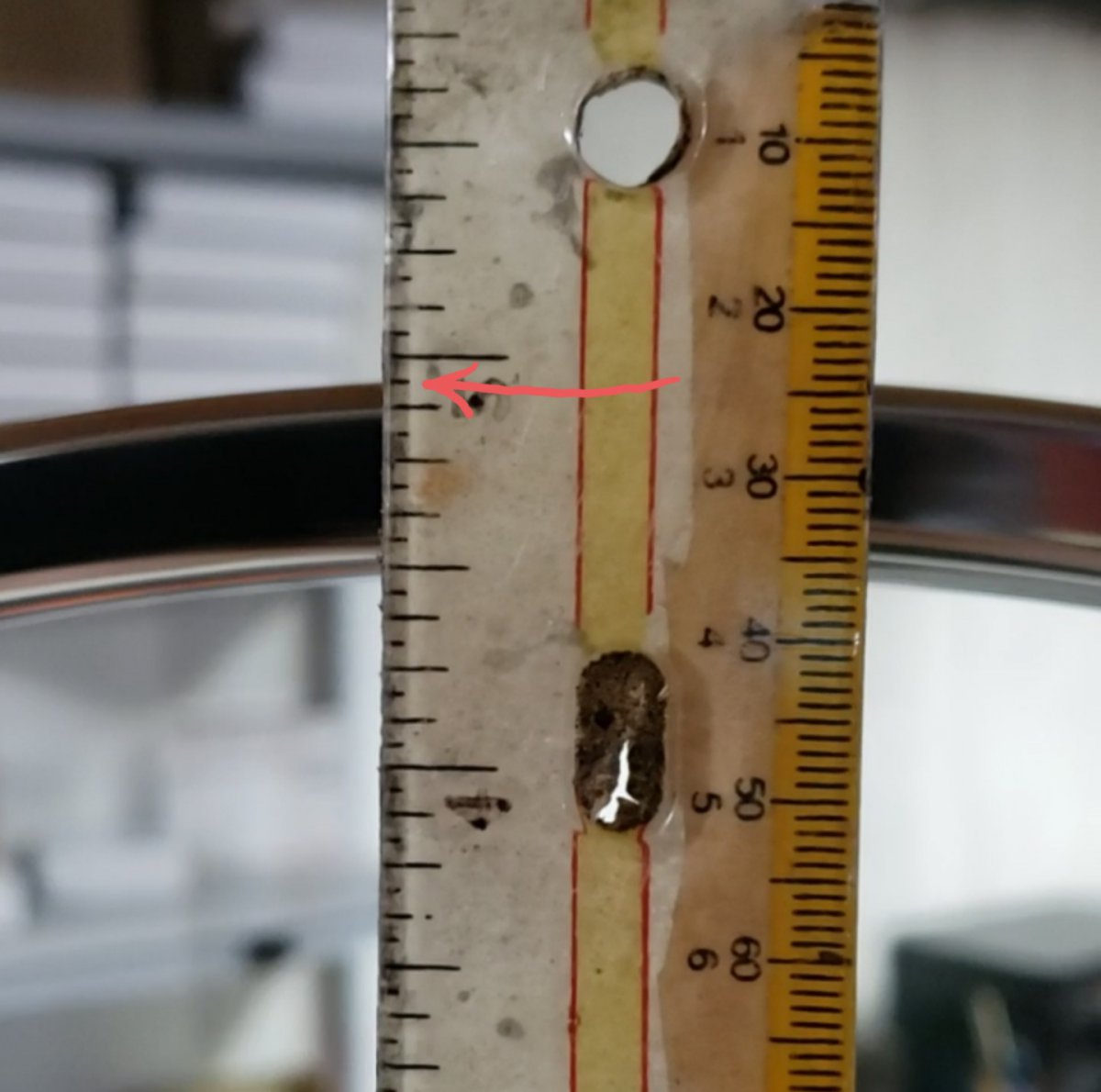

Then you want to put the rim on the truing stand and loosen all the spokes all the way loose. Check for flat spots by resting a ruler on the fork and holding up close to the rim. Spin the wheel. Get at eye level with the rim and line up a mark on the ruler with the top of the rim. As its spinning, if the rim moves up and down, there is at least one flat spot.

If you got wide rims with cruiser tires, a 1 to 2 mm flat spot is fine. As you can see my flat spot is 1/16" which is right in between so I left it like that.

Watch this video if you need to fix the flat spot(s). Youtube link

He'll even show you how to make a cool little tool you'll need.

Straightening A Bent Rim

Now on to side to side alignment. This is if your rim is too bent to fix just by tightening the spokes. So first, keep wheel on the stand. Spin the wheel and find the side that the rim kicks out at the most. Tighten the bolt on that side until it rubs against the area that sticks out the most. Mark the beginning and end of the rubbing.

Then mark the beginning and end of where the rim starts to move closer that area where it rubs from being straight.

Get out 2 horses (portable work stands) and 2 adjustable clamps. Put the rim on top of the horses, the bent out side facing up. the rim should hang over starting on the outer lines (which would be the beginnings of the bend). Clamp it down snug but not too tight that you bend the rim walls.

Get a small block of wood that fits very snug inside the walls of the rim (you may have to sand it down or taper it, cut out a curve that matches the rim's curve.

This will be your wedge to protect your rim from bending when you align it. Jam it in between the inner lines. It should all look like this.

Now take a wood board at least 1/4" thick. Its important that you don't use one much thinner, you may bend your rim too much when aligning. Preferable thickness 1/4" to 3/4". Now lay it over the wheel. It just needs to cover the rim. You want the board wide enough to at least completely cover the inner lines. A little more is better. Now tap the rim where the wedge is with a sledgehammer. Don't swing the hammer over your shoulder, just tap it lol.

Start out lightly until you get a feel for how hard you need to hit it for it to bend back enough. You want the rim to flex when you hit it. Don't worry, the wedge and the wood board will protect the rim from any possible damage. Keep putting it on the truing stand and checking it. This will likely be a lengthy process, but this is the only method I tried that seemed to be the most controlled. I tried bending the rim with my knee with my weight on the horses too, but it was very hard to gauge how much force I'm using and I ended up making it worse more times than better.

Truing with the Spokes

Once you're ready to true the rim with the spokes, put the rim back on the stand and find the area that rubs again but instead of marking it, just put your thumb there and turn the wheel so its at the highest point. Notice how one spoke is attached to one side and the other is attached to the opposite side. Tighten the spoke on the opposite side of the bend with your spoke tool. That will pull the rim to that side. Initially, tighten it until its about half way tight. Then from there turn it a quarter turn or so and keep checking it until that area straightens out. Tighten all the spokes that need to be tightened for straightening and then turn all the other spokes a little at a time and readjust as needed until all spokes are tight enough and the rim is pretty straight. The rim doesn't need to be perfectly straight, but the closer the better.

And that's how you can fix your rim for little . Remember, its more about patience than skill!

. Remember, its more about patience than skill!

Making A Truing Stand

Just take any old bicycle fork and jb weld 2 nuts on it and put matching bolts through it. Cap off the ends with something that won't scratch your rim. I used tire valve caps which actually threaded right on to the bolts. Then make, buy, or use any kind of stand to put it on. I used my bicycle stand. Now its a 2 in one stand lol.

Fixing Flat Spots

Next, buy a spoke tool if you don't have one. You can get 2 for $6 on amazon. It tightens/loosens spokes of any size.

Amazon link

Then you want to put the rim on the truing stand and loosen all the spokes all the way loose. Check for flat spots by resting a ruler on the fork and holding up close to the rim. Spin the wheel. Get at eye level with the rim and line up a mark on the ruler with the top of the rim. As its spinning, if the rim moves up and down, there is at least one flat spot.

If you got wide rims with cruiser tires, a 1 to 2 mm flat spot is fine. As you can see my flat spot is 1/16" which is right in between so I left it like that.

Watch this video if you need to fix the flat spot(s). Youtube link

He'll even show you how to make a cool little tool you'll need.

Straightening A Bent Rim

Now on to side to side alignment. This is if your rim is too bent to fix just by tightening the spokes. So first, keep wheel on the stand. Spin the wheel and find the side that the rim kicks out at the most. Tighten the bolt on that side until it rubs against the area that sticks out the most. Mark the beginning and end of the rubbing.

Then mark the beginning and end of where the rim starts to move closer that area where it rubs from being straight.

Get out 2 horses (portable work stands) and 2 adjustable clamps. Put the rim on top of the horses, the bent out side facing up. the rim should hang over starting on the outer lines (which would be the beginnings of the bend). Clamp it down snug but not too tight that you bend the rim walls.

Get a small block of wood that fits very snug inside the walls of the rim (you may have to sand it down or taper it, cut out a curve that matches the rim's curve.

This will be your wedge to protect your rim from bending when you align it. Jam it in between the inner lines. It should all look like this.

Now take a wood board at least 1/4" thick. Its important that you don't use one much thinner, you may bend your rim too much when aligning. Preferable thickness 1/4" to 3/4". Now lay it over the wheel. It just needs to cover the rim. You want the board wide enough to at least completely cover the inner lines. A little more is better. Now tap the rim where the wedge is with a sledgehammer. Don't swing the hammer over your shoulder, just tap it lol.

Start out lightly until you get a feel for how hard you need to hit it for it to bend back enough. You want the rim to flex when you hit it. Don't worry, the wedge and the wood board will protect the rim from any possible damage. Keep putting it on the truing stand and checking it. This will likely be a lengthy process, but this is the only method I tried that seemed to be the most controlled. I tried bending the rim with my knee with my weight on the horses too, but it was very hard to gauge how much force I'm using and I ended up making it worse more times than better.

Truing with the Spokes

Once you're ready to true the rim with the spokes, put the rim back on the stand and find the area that rubs again but instead of marking it, just put your thumb there and turn the wheel so its at the highest point. Notice how one spoke is attached to one side and the other is attached to the opposite side. Tighten the spoke on the opposite side of the bend with your spoke tool. That will pull the rim to that side. Initially, tighten it until its about half way tight. Then from there turn it a quarter turn or so and keep checking it until that area straightens out. Tighten all the spokes that need to be tightened for straightening and then turn all the other spokes a little at a time and readjust as needed until all spokes are tight enough and the rim is pretty straight. The rim doesn't need to be perfectly straight, but the closer the better.

And that's how you can fix your rim for little

Last edited:

Links to Amazon may include affiliate code. If you click on an Amazon link and make a purchase, this forum may earn a small commission.