Well, after a few years of motorized bike experience and building countless kits, I've always had a problem with the crappy gaskets they come with, they would always either rip on me whenever I needed to remove the cylinder or intake or they were soo thin that it wouldn't seal properly even when cranking down on the bolts as hard as possible.

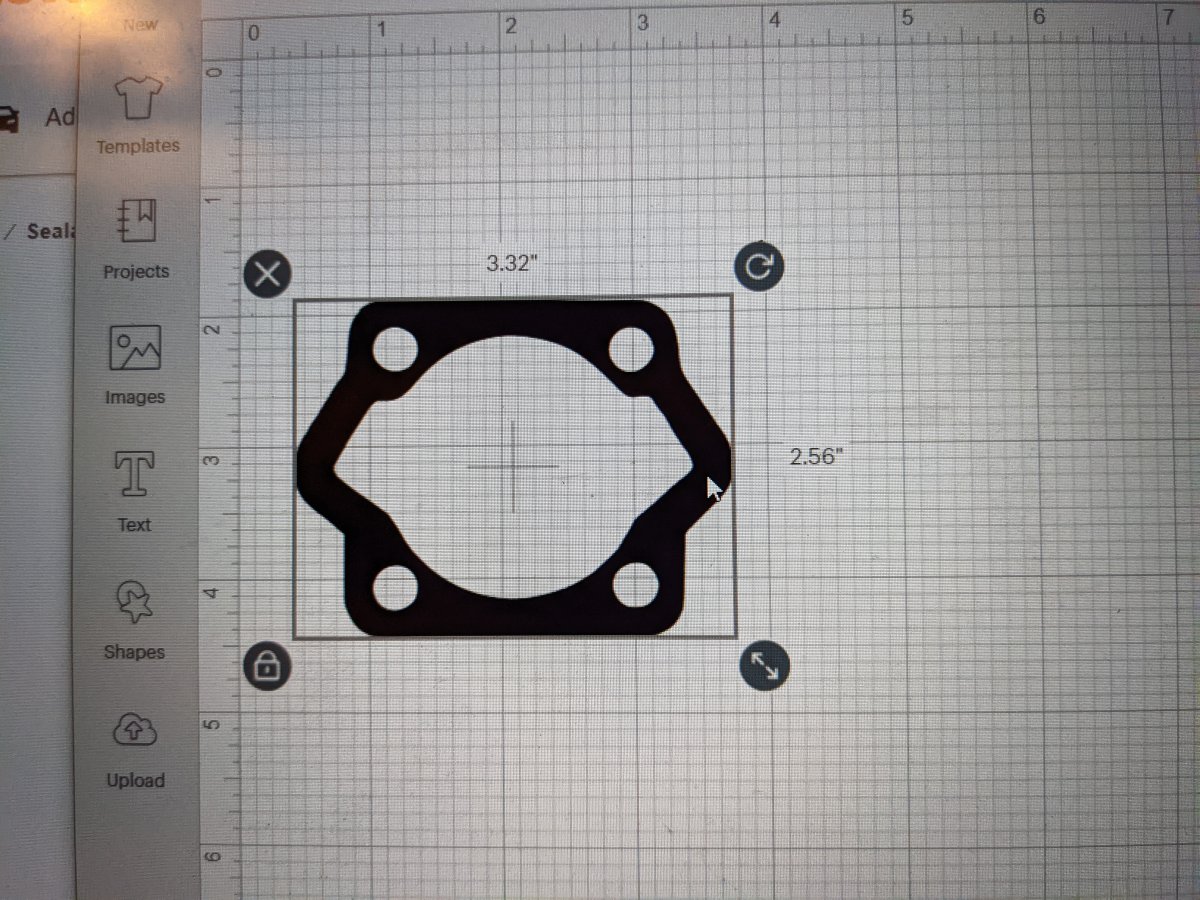

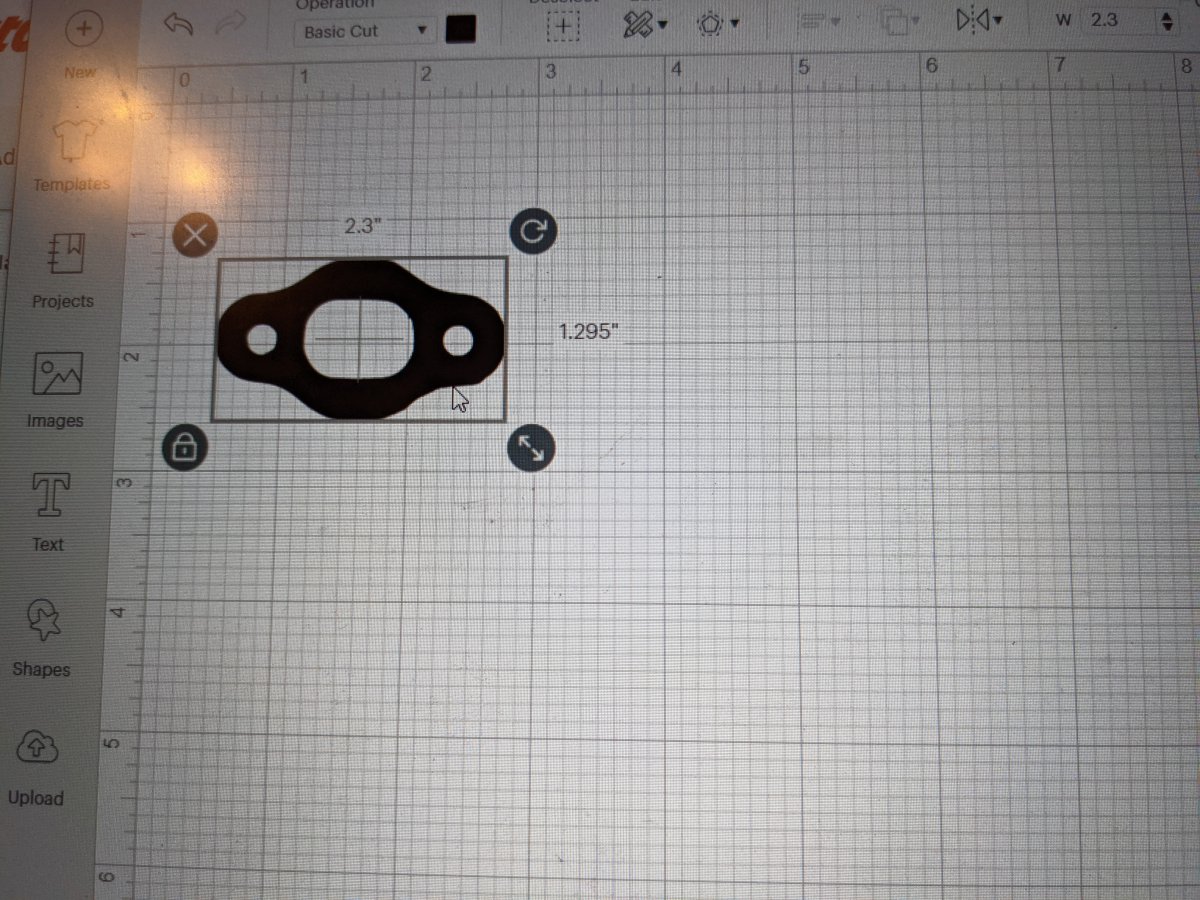

Sooo, I decided to make my own!

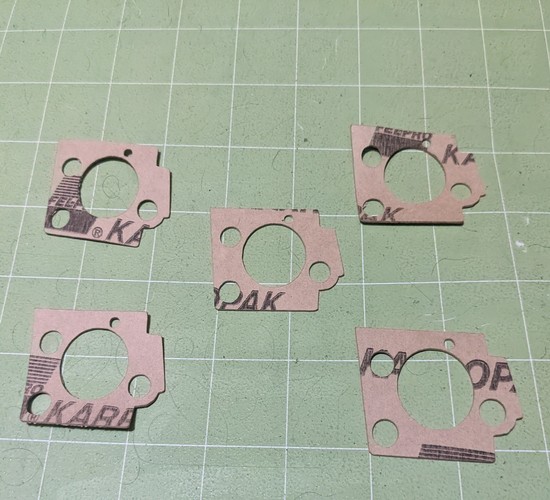

There cut on my CNC cutter and quality checked by yours truly, I use the best material's that I can find (fel-pro)

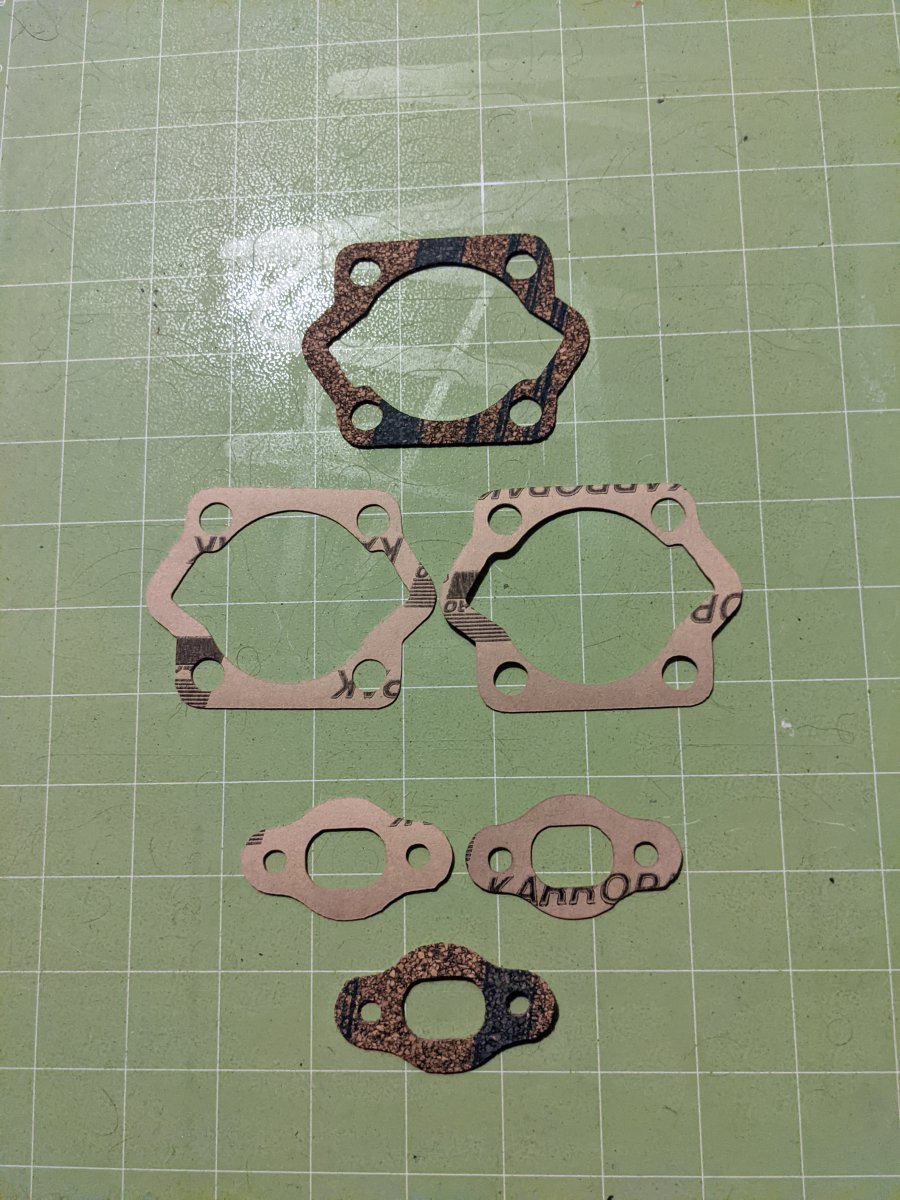

The rubberized cork gasket and the Karropak withstands the bend test with flying colors!

I'm currently offering these gaskets for the intake as well as the base gasket.

You get 2 Karropak base gaskets and rubberized cork base gasket as well as 2 Karropak intake gaskets and 1 rubberized cork intake gasket all for 15$ shipped (lower 48)

Due to popular demand, I will now be offering my chainsaw gaskets made of Karropak, these will fit the chainsaw carb conversions (Tillotson HS254B carbs to be specific)

You get 5 gaskets for 10$ shipped (lower 48)

For sales or inquires: Either PM me or email me at markmakesgaskets@gmail.com

Sooo, I decided to make my own!

There cut on my CNC cutter and quality checked by yours truly, I use the best material's that I can find (fel-pro)

The rubberized cork gasket and the Karropak withstands the bend test with flying colors!

I'm currently offering these gaskets for the intake as well as the base gasket.

You get 2 Karropak base gaskets and rubberized cork base gasket as well as 2 Karropak intake gaskets and 1 rubberized cork intake gasket all for 15$ shipped (lower 48)

Due to popular demand, I will now be offering my chainsaw gaskets made of Karropak, these will fit the chainsaw carb conversions (Tillotson HS254B carbs to be specific)

You get 5 gaskets for 10$ shipped (lower 48)

For sales or inquires: Either PM me or email me at markmakesgaskets@gmail.com