Urban Fatbiker

Well-Known Member

There's a hole in my Buzzbike 100 mile thread, where I said I'd be back tomorrow, came back over a week later?

I didn't want the continuity of that thread wrecked by my dumbassedry.

Ok I've built ONE mb....not counting the etrikes.

But I've dimpled hundreds of shafts, sent back dozens to machinists over a LONG career, so yes, I Am A Dumbass.

Let's make that worse won't we? Yeah I've built ONE m/b...but I assembled, installed, programmed, ADVISED, reviewed, at least 10 robotic workcells...huge industrial tube forming machines...making everything from handlebars to exhaust to frames of almost every m/b, atv, golf cart, bicycle, thats made here...or brazil...or mx.

Never owned a Honda or a Yamaha. But I've been in their facilities from Marysville to Manaus to Hammamatsu.

Someone might think I'm a real dumbass, I should have a Goldwing and a Razor as my rides, but I was into cars. I did get employee discounts on Holley carb, and threw a set of headers into their chroming process when I was in Aberdeen for a week.

I preferred Manaus. Jus saying.

But I ramble.

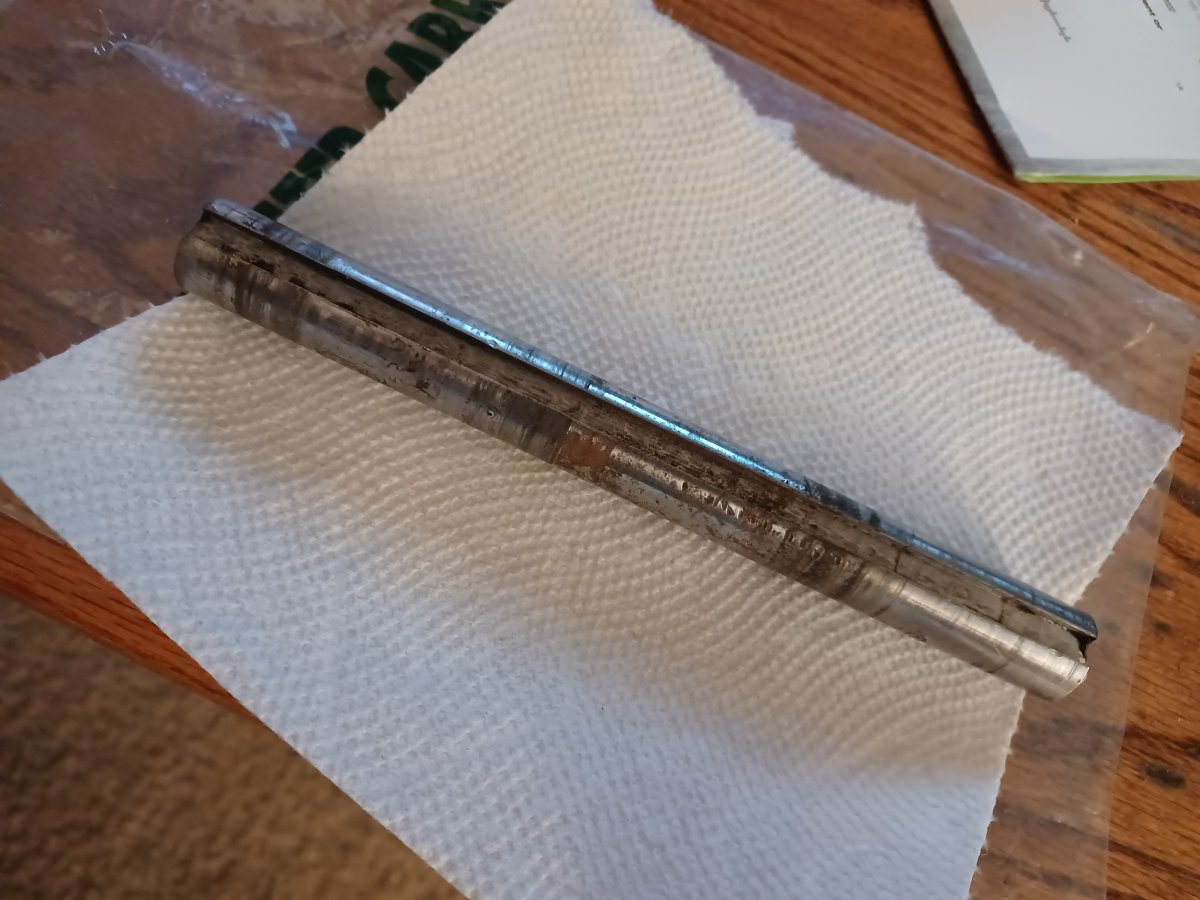

Back to the point, that should have veen seated in a dimple.

I did ride that day, after putting the 21T gear on my jackshaft. I used thread lock. But no dimples.

After 10 miles, R side chain came off. When I looked, I saw 9T sprocket and bearing almost out of bracket, entire shaft slid right.

At least I was a dumbass with tools.

When I got my new shaft and bearings a few days later, I mounted and aligned everything, marked, took apart.

A 5mm punch fits great in the 1/4" set screw hole. Punch using sprocket as guide, remove. Use small bit to start dimple, just enough to seat next bit 1/4".

Drill ONLY to countersink, less than bit diameter, but slightly larger than cup point of set screw.

Reassemble.

Using non-dumbass tech, please.

I added a shim and lock collar to LH side too.

Get longer set screws for the larger sprocket, and put a few in your tool bag.

Note on shaft:

I saw many grumbles about SBP shaft under tolerance, and this one seemed also.

But shaft I got from McMaster-Carr was identical and both seemed 0.0025 undersize.

I used some punch strikes in bearing area. Lots of threadlocker, and I clamped sprocket to bracket when tightening set screws.

As Murphy stalks me, I'm already considering a hi-tolerance shaft, but I have to buy a long length, and it ain't cheap.

I won't dare rag on SBP. Pricing some of this stuff, yeah they could make a hi-tolerance kit, better bearings, etc...and it'd be way too expensive.

Damn if only I'd got into m/b years ago. Back when I spent all my working time inside places that made Yamahas and Hondas...somewhere in Brazil peeps are riding pretty yamahas with chrome handlebars bent on a robotic workcell I programmed and installed with many many cups of what they call coffee, we call kick ass double expresso kind of shizz.

And those nuts at Pro Circuit, just listening to their motocross stories at lunch, I coulda used more than shirts as sovieniers.

I didn't want the continuity of that thread wrecked by my dumbassedry.

Ok I've built ONE mb....not counting the etrikes.

But I've dimpled hundreds of shafts, sent back dozens to machinists over a LONG career, so yes, I Am A Dumbass.

Let's make that worse won't we? Yeah I've built ONE m/b...but I assembled, installed, programmed, ADVISED, reviewed, at least 10 robotic workcells...huge industrial tube forming machines...making everything from handlebars to exhaust to frames of almost every m/b, atv, golf cart, bicycle, thats made here...or brazil...or mx.

Never owned a Honda or a Yamaha. But I've been in their facilities from Marysville to Manaus to Hammamatsu.

Someone might think I'm a real dumbass, I should have a Goldwing and a Razor as my rides, but I was into cars. I did get employee discounts on Holley carb, and threw a set of headers into their chroming process when I was in Aberdeen for a week.

I preferred Manaus. Jus saying.

But I ramble.

Back to the point, that should have veen seated in a dimple.

I did ride that day, after putting the 21T gear on my jackshaft. I used thread lock. But no dimples.

After 10 miles, R side chain came off. When I looked, I saw 9T sprocket and bearing almost out of bracket, entire shaft slid right.

At least I was a dumbass with tools.

When I got my new shaft and bearings a few days later, I mounted and aligned everything, marked, took apart.

A 5mm punch fits great in the 1/4" set screw hole. Punch using sprocket as guide, remove. Use small bit to start dimple, just enough to seat next bit 1/4".

Drill ONLY to countersink, less than bit diameter, but slightly larger than cup point of set screw.

Reassemble.

Using non-dumbass tech, please.

I added a shim and lock collar to LH side too.

Get longer set screws for the larger sprocket, and put a few in your tool bag.

Note on shaft:

I saw many grumbles about SBP shaft under tolerance, and this one seemed also.

But shaft I got from McMaster-Carr was identical and both seemed 0.0025 undersize.

I used some punch strikes in bearing area. Lots of threadlocker, and I clamped sprocket to bracket when tightening set screws.

As Murphy stalks me, I'm already considering a hi-tolerance shaft, but I have to buy a long length, and it ain't cheap.

I won't dare rag on SBP. Pricing some of this stuff, yeah they could make a hi-tolerance kit, better bearings, etc...and it'd be way too expensive.

Damn if only I'd got into m/b years ago. Back when I spent all my working time inside places that made Yamahas and Hondas...somewhere in Brazil peeps are riding pretty yamahas with chrome handlebars bent on a robotic workcell I programmed and installed with many many cups of what they call coffee, we call kick ass double expresso kind of shizz.

And those nuts at Pro Circuit, just listening to their motocross stories at lunch, I coulda used more than shirts as sovieniers.