Sachs-rider

New Member

Update - Here's how to get the best performance out of your Sachs 301/a or Pro Rotar

Here's how to get the best performance out of your Sachs 301/a or Pro Rotary RH-01 equipped bicycles without major modifications (Insane Tuning pipes, machining engine etc)

Updated 4/9/2009

First, get the service manuals and as much information from the internet as you can find (see links). By Performance I am not just talking about maximum speed, there is really no point in trying to faster than 30km/hr, the Sachs is not geared for high speed, any faster than 30km/hr is just going to make a lot of noise and reduce the engine life. If you want to go faster, be realistic and get yourself a 50cc moped or larger motorcycle. The point of the Sachs is that it is a tiny, add-on engine, light-weight and economical if driven at around 20-30km/hr.

1. Make sure your bike is well maintained, no brakes rubbing, or loose parts (check chain, wheels, pedals bars, mud guards etc). Make sure your brake cables are well lubricated and the brakes don't stick on, (check by spinning the wheels and applying the brakes).

2. Check your tyres are at the correct pressure and fitted properly (no valve bumps) and your wheels are free running, true and not damaged. Low tyre pressure will reduce your speed!

3. Mix your unleaded fuel and 80:1 oil well (you will find different performance between the petrol retailers) (Also your may find the clutch behaves differently according to the oil mix as the clutch systems receives some of that oil from the crank case)

4. Its worth stripping down your carburettor if the machine is old or has not been used for a while (careful not to break those gaskets) and making sure the float chamber is clean as well as the main jet, and idle jet drillings and the needle valve. On The Bing carb, (don't over tighten the float chamber screws and crack the plastic). You won't get better performance messing around with the jets, I can't over emphasise the benefit of a surgically clean carb!

5. When the carb is removed, unscrew the induction port plastic plate and check the reed valve is secure and clean.

6. Set the idle speed with the engine running, set the throttle idle speed so that the wheel just rotates when lifted off the ground at idle and the engine idles smoothly. (Set up on a warmed up engine), you will have to pump the throttle each time you trim the idle screw to allow it to settle.( I find with my bike at idle I get a speed of around 13-16 KM/hr without peddling). The cable tension adjuster at the handle bar end also affects your idle speed!

7. Make sure all the Allen key bolts around the engine are tight including the ones underneath.. near the exhaust and there are no oil leaks.

8. Clean the top of the carb case with a small paint brush; lube (wd40) the control cables etc.

9. Check your air filter is clean and fitted properly.

10. Its worth modifying or changing your CDI unit (blue or red ignition box near air filter) to get max revs (the stock unit is set to restrict the engine as per local regulations). The modification needs a patient steady hand, if rushed you could easily destroy the unit! See Mod information below. Otherwise make your own ignition unit (see links below)

11. Check the electrical wires between coil, CDI and Carb are all in good condition and connected properly, if the crimp connectors are loose on the CDI, close the connector up a little with pliers so they are tight on the CDI when fitted.

12.Check the ignition coil/flywheel pickup gap (0.4mm max), remove the plastic panel where the pull start goes, you will see the fly wheel and close by, the ignition coil, the part close to the flywheel is where the ignition pulse is picked up, check the gap between the flywheel and the pickup, you can adjust it with Allen keys or torx keys on the coil, don't set it so the pickup scuffs the fly wheel magnet, rotate the fly wheel whilst setting the gap (the flywheel has a magnet in it). Use a feeler gauge.

13. Fit a clean spark plug and check the gap (0.5-0.6mm), Use the correct spark plug. It's worth trying a very slightly larger electrode gap (your local motorcycle guys will tell you, it's to do with your local fuel and Altitude. Learn to "read" spark plug electrode colouring you want "biscuit brown", it's the best way to check your combustion is right. Oil around the spark plug means its not sealing properly (low compression), don't over-tighten the spark plug, rather replace it with a new one with a new seal washer, if possible fit using a torque wrench. Don't underestimate the importance of the right spark plug and electrode gap, it really does make a huge difference to the performance of the engine.

14. Make sure your exhaust is well sealed and clean and the securing screws are tight.

15. Check your fuel filter is clean and working

16. Check your throttle cable is ok and does not have too much slack in it, (adjust at handle bar), same for the on/off choke control cable, check its set up correctly, when in the engine off position at the handle bar control, the spring on the carb rod should not pull up more than 1 mm above the plunger top position. On my bike, the throttle twist required to get maximum revs is only about 1/2 of the total rotational range of the control. I have put tape markers on my twist throttle control to see where I tend to twist it. Make sure the choke slides fully up and down inside the carb (remove the air filter and look into the carb, on full choke, the slide (with hole in it) should be fully down, and with choke off, the slide should be fully clear of the carb induction port the slide range is set by a circlip on the black plastic choke control plunger)

17. Riding, when starting, take 2-5 minutes to warm the engine up by riding slowly on the flat, always pedal to start off to avoid staining the clutch.

18. Riding, when the road is bumpy take your weight off the saddle and stand on the pedals with your knees slightly bent, to reduce the shocks to the rear of the bike. Never ride over pot holes at high speed, remember your cast alloy back wheel won't straighten out once bent. I have found that sometimes if I hit a hard bump, the engine dies a little, I think this is due to a fuel-splashing disturbance in the carb, it take a few minutes further riding slowly to get full power out of the engine again.

19. Riding, Air resistance becomes significant above 15 km/hr, reduce your profile by crouching towards the handle bars and (if you, like me have a women's bike) rest your feet on the cross bar.

19. Take basic tools and spares with you!.

20. Check your transmission oil, use the right one.

21. It has been suggested to drill more air holes into the induction port muffler box (black plastic box and lid), I have found that this box is an important part of the air-flow design of the carb, I found that if I remove the lid whilst the engine is running at idle, the engine slowly stops due to overly lean idle mixture, this can lead to over-heating and temporary loss of compression and difficult starting.

22. Reduce your bike's weight, remove unused parts (I removed the clear plastic side guards below the parcel rack on mine, because they resonate with the engine vibration and make a terrible noise!)

23. Starting, if you are finding your machine difficult to start, remember - Fuel, Ignition, Compression, and Timing., if you are away from home and are really struggling to get the Sachs engine going, try the following procedures.

Choke use

Coke is only needed for starting, do not pull starting cord more than 5 times with choke on as flooding can occur - (you will smell the fuel nearby).

Cold Starting - full choke, pull start until engine starts, run until idle speed starts to drop, then quickly move to half-way between coke and run (1/2 Choke), let engine idle for a few seconds, when idle speed starts to drop again set to run position and rev the engine a little to stabilise warm up.

Cool start (engine stopped between 5-20 mins), two pulls on run position, then two pulls on choke, then pull again on run position, should start ok.

Warm start - (engine off for less than 5-10 mins) pull on run position only unless its not starting, give on pull on coke, then pull start on run, if it starts on choke, set run position as soon as the engine is running and idle speed is dropping.

More choke is needed starting in cold weather.

Over heating can occur if you run the engine at idle with the plastic back cover removed, the engine will slowly die and may overheat, this will result in the engine being difficult to start for 10 mins due to low compression (feel low compression when pulling the starting cord). Just let it cool down for 10 mins and do a cool start

If you suspect a flooded engine (too much choke used, or bumpy riding) let the machine stand for 5 mins to allow the fuel to evaporate and try starting again in the "run" position, if it's still tricky, get only one pull with say, half choke.

Trouble starting?

1. Relax, find a quite. Safe place with flat ground and put the bike up on the stand. If you have been riding your machine ok and are finding it difficult to start, I find that nine times out of ten it's a fuel issue (not enough drawn in by not using enough choke, or flooding by using too much!). If you suspect a flooded engine, just wait 5-10 minutes or ride on pedals and try starting again.

2. Check there is fresh uncontaminated (water etc) fuel in the tank, and you can see it in the fuel filter, pipe.

3. If you can remove the spark plug, check there is spark but touching the bottom of the removed plug onto the engine chassis (with the spark plug cable connected to the top of the pug as usual) and gently pulling the starting cord, you should see sparks (avoid pulling the engine start with the spark plug disconnected of the bottom of the plug not grounded (can damage the CDI)

4. Assuming you do have spark, try unscrewing the back air filter box and remove the air filter, block the carb inlet port with a finger and pull the starting cord once or twice slowly. This has a strong choking effect and draws fuel into the carb, (you should see it wet in the inlet when you remove your finger). Replace air filter and try starting again This very often get the engine running especially if the machine has been standing for a while. Check your choke is actually setting right, the bing carb has a control plunger the height of this sets the coke, make sure the curclip on that plunger is set to allow the choke slide to go all the way down.

5. If you don't have spark, its time to check your wiring, inspect the connectors on the CDI and on the coil unit (might have to remove the plastic side panel). Try disconnecting the blue wire that runs into the top of the carb box to the carb, that's the kill switch wire and if the switch in the carb is stuck on, there will never be spark. Note that if you do get the engine running with the kill switch wire disconnected, you will need to touch that wire (from the CDI) to the engine chassis to stop the engine (never pull the spark plug cable off to stop the engine, you might damage the CDI unit). Make sure none of the connectors are shorted out to one another or the engine chassis. If your On/Off/Choke cable is not correctly adjusted you can find that the engine kills when you select the normal running position after starting on choke.

6. If you are finding your carb is flooding and fuel is dripping out, the carb needle valve is fouled and not closing properly, you need to strip down the carb and clean it. Remember to work safely with fuel!

7. If you are not getting any fuel to the carb, check your control cables, it could be the stop cock inside the carb, your pipes, filter etc.

8. If you are finding the pull start much easier to pull and the motor turns a little after you pull, you are loosing compression, check your spark plug is ok and fitted properly (Don't get any dirt or foreign objects in to the cylinder from the spark plug hole!) This can be caused by an over-heating engine, due to overly lean mixture( black plastic lid removed, or blocked jets?)

Quick check list on troublesome starting...

FUEL

1) Fuel, Oil --no fuel, too much oil.

2) Fuel Pipe-blocked.

3) Fuel filter-blocked.

4) Carb stop cock/control cable-damaged, maladjusted.

5) Carb choke slide, plunger/control cable-damaged, maladjusted.

6) Carb needle valve - fouled, damaged, blocked

7) Carb jets- fouled, damaged, blocked

8) Blocked air filter

9) Flooding carb - Fouled needle valve

IGNITION

1) CDI wiring/connectors - connected wrong, disconnected, damaged CDI (check with meter).

2) Ignition coil/pickup/connectors-damaged coil, wires, loose screws on coil (check with meter).

3) Spark plug/cable/connector - Fouled, damaged plug, damaged cable or connector

4) Carb Kill switch-stuck in Kill position inside carb, wire shorted to chassis, control plunger.

COMPRESSION

1) The compression can be lost by over-heating the engine , this is caused by over-lean mixture, let the engine cool. Spark plug (Loose fit, gas escaping) ( make sure plug hole rim is clean, tighten plug with a torque wrench)

2) Cylinder Gaskets, seals.

TIMING

1) Coil gap/flywheel - loose coil mounting, damaged flywheel, coil

2) CDI UNIT-Damaged CDI, wires

3) Reed valves

Modifying the Red Motoplat CDI for Sachs 301/a for unrestricted engine running

The cost of replacing a destroyed CDI is quite high, so I recommend that this is undertaken with the view that you won't be annoyed if you do destroy the unit. The best approach is to take the time to build yourself a basic replacement CDI (see links) , fit and run your bike with that unit for a while before attempting to modify the Motoplaat unit. That way, if you do destroy the stock CDI, you can still ride on your homemade one!

There are a few comments and pictures on the internet suggesting it is possible to drill a hole into a stock CDI unit, apparently, if done in the correct location the speed restriction can be removed! This is a completely crazy idea, I do not advise you try just drilling holes in your CDI, you will destroy it and feel like an idiot, for the rest of the day.

? Don't drill holes!

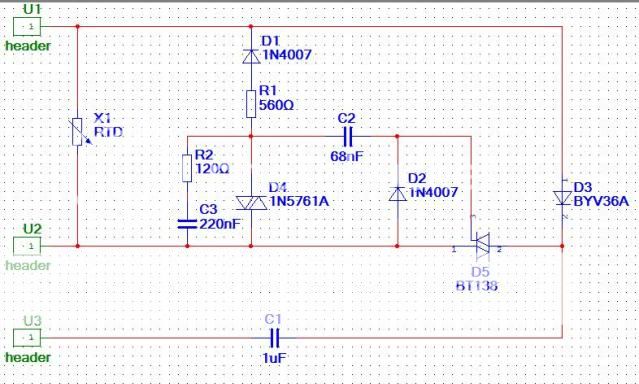

See the links for the do it yourself CDI, which I built and fitted to my Sachs 301, it works well and for me I did use the extra delay circuit to get better timing with my machine. I fitted the LC delay circuit with a wire link option to run with or without and found better performance with the delay connected - I am sure that the so-called "chip-tuning" aftermarket CDI units sold in Holland and Germany are the same as the simple circuits in road-runners page!

The reason I decided to look at modifying my red Motoplat CDI, was that I am sure that there is some advance/retard operation going on in that unit which that home-made version does not offer.

I have found that the idling performance is slightly better with the modified red Motoplat than with the road-runner circuit.

I say it's a modification, really it's an adjustment.

You will need a grinder, and sharp Scalpel NTcutter/Stanley knife and 45 mins free time for the job, not less. A good light and magnifying glass will help.

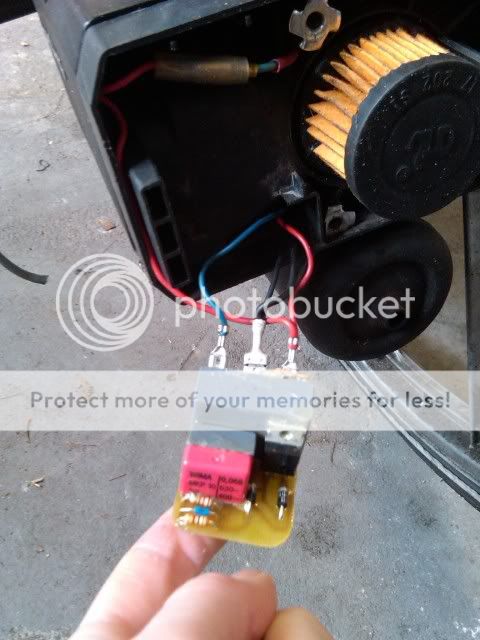

First grind the red plastic off the side and top of the CDI (check the photo you are doing the right side!) Don't grind the circuit board, only the outer plastic and resin areas.

Using a blade, CAREFULLY slice away the resin, layer-by-layer, rather go too slow, than in a hurry.

If you dig too deep, too fast, you could easily cut a capacitor and destroy the unit

When you get close to the blue trim pots, go very slowly, using a tiny blade and needles pick out all the resin from the trim pot white slot, don't be tempted to try and turn the trim pots before you have cleaned away all the resin, the white trim pot plastic is soft, be careful not to cut it. You will need to cut and loosen the resin behind the trim pots as well so you don't rip them out when you turn them. If you hit metal whilst cutting away the resin, avoid that area, it's one of the capacitors!

When you're ready, insert a trimmer or small screwdriver and VERY GENTLY apply turning pressure in both clock-wise and anti-clockwise directions on the trim pots.

Make a note of the trim pot positions.

When you get them loose, very slowly turn the trimmers in each direction a small way, (don't force them they have an end-point), getting further and further round until you can easily turn them both through their whole range, then return the trim pots to the original positions and clean up your CDI.

The engine speed limit control is on the Trim pot marked 2k or 2k5, nearest the metal contacts on the CDI, all you need to do know is turn that one fully anticlock-wise to its end-stop position ( about 7 o'clock).

Refit the unit and go ride, (start slow and warm the engine before , take your tools and home-made CDI as a spare) you should be getting 29-30 km/hr on the flat no wind with good spark plug and carb, anything over 25km/hr on the flat shows that the restriction is off.

Carry your home-made CDI with you and make some comparison tests.

Re-seal your "adjusted" CDI with a glue gun to avoid dirt going into the exposed trim pots.

I have not tried changing the other trim pot (200e, 200 ohm); I think it is for the spark delay, period, current. So at the point, I recommend you leave it as it is, or experiment and let me know how your do.

To summarise; for speed you need.....

1> Free-running true wheels

2> Pumped tyres

3> Correct fuel/oil

4> Modified CDI, correct flywheel/coil pick up gap setting

5> Correct spark plug and gap setting

6> Clean carburettor and air filter

7> Flat smooth road, no wind, low-drag riding position and clothing.

With all these conditions you should get a steady 28 - 30 km/hr drive on your Sachs 301/a 26x1 3/8 wheel machine.

Ignition electrical tests

1) Use an analogue multimeter so you can see the ignition pulses

Test for resistance:......

2) Test Spark plug Resistance from top to electode - 1ohm or less

3) Test Spark plug connector to chassis resistance - 4000 ohms (4K)

4) Test Spark plug connector to red coil wire (CDI output) resistance - 4000 ohms (4K)

5) Test Spark plug connector to Blue coil wire (CDI intput) resistance - 4000 ohms (4K)

6) Test Coil Pulser wire (Blue) to chassis - 110,000 ohm (110K)

7) Test Coil Trigger wire (Red) to chassis - <1ohm

8) Test Coil Trigger wire (Red) to Pulser wire (Blue) - 110 ohm

9) Using AC volts on your meter set to up to 10 VAC, Test output when cranking engine with CDI, sparkplug and kill switch removed/disconnected - You should see the meter pulse 3-5 VAC on the blue wire, (CDI input from pulser coil). I cannot read the CDI output pulses with my multi-meter, I suspect the pusles are too short to move my meter, maybe try a neon bulb between the red wire and chassis - you may be able to see the neon flash as the CDI output pulses (don't forget to keep the red wire connected to the coil whilst doing this test).

10) Check CDI resistances Pos means positive wire on your meter, neg means the negative wire (black)

Pos means positive wire on your meter, neg means the negative wire (black)

Pos=Bluetag,Neg=redtag - 100k ohm.

pos=redteg,Neg=bluetag - 25K ohm.

pos=bluetag,Neg=Earthtag - 100k ohm.

pos=Earthtag,Neg=bluetag - 20k ohm.

pos=redtag,Neg=Earthtag - 2k ohm.

pos=Earthtag,Neg=Redtag - 2k ohm.

Here's how to get the best performance out of your Sachs 301/a or Pro Rotary RH-01 equipped bicycles without major modifications (Insane Tuning pipes, machining engine etc)

Updated 4/9/2009

First, get the service manuals and as much information from the internet as you can find (see links). By Performance I am not just talking about maximum speed, there is really no point in trying to faster than 30km/hr, the Sachs is not geared for high speed, any faster than 30km/hr is just going to make a lot of noise and reduce the engine life. If you want to go faster, be realistic and get yourself a 50cc moped or larger motorcycle. The point of the Sachs is that it is a tiny, add-on engine, light-weight and economical if driven at around 20-30km/hr.

1. Make sure your bike is well maintained, no brakes rubbing, or loose parts (check chain, wheels, pedals bars, mud guards etc). Make sure your brake cables are well lubricated and the brakes don't stick on, (check by spinning the wheels and applying the brakes).

2. Check your tyres are at the correct pressure and fitted properly (no valve bumps) and your wheels are free running, true and not damaged. Low tyre pressure will reduce your speed!

3. Mix your unleaded fuel and 80:1 oil well (you will find different performance between the petrol retailers) (Also your may find the clutch behaves differently according to the oil mix as the clutch systems receives some of that oil from the crank case)

4. Its worth stripping down your carburettor if the machine is old or has not been used for a while (careful not to break those gaskets) and making sure the float chamber is clean as well as the main jet, and idle jet drillings and the needle valve. On The Bing carb, (don't over tighten the float chamber screws and crack the plastic). You won't get better performance messing around with the jets, I can't over emphasise the benefit of a surgically clean carb!

5. When the carb is removed, unscrew the induction port plastic plate and check the reed valve is secure and clean.

6. Set the idle speed with the engine running, set the throttle idle speed so that the wheel just rotates when lifted off the ground at idle and the engine idles smoothly. (Set up on a warmed up engine), you will have to pump the throttle each time you trim the idle screw to allow it to settle.( I find with my bike at idle I get a speed of around 13-16 KM/hr without peddling). The cable tension adjuster at the handle bar end also affects your idle speed!

7. Make sure all the Allen key bolts around the engine are tight including the ones underneath.. near the exhaust and there are no oil leaks.

8. Clean the top of the carb case with a small paint brush; lube (wd40) the control cables etc.

9. Check your air filter is clean and fitted properly.

10. Its worth modifying or changing your CDI unit (blue or red ignition box near air filter) to get max revs (the stock unit is set to restrict the engine as per local regulations). The modification needs a patient steady hand, if rushed you could easily destroy the unit! See Mod information below. Otherwise make your own ignition unit (see links below)

11. Check the electrical wires between coil, CDI and Carb are all in good condition and connected properly, if the crimp connectors are loose on the CDI, close the connector up a little with pliers so they are tight on the CDI when fitted.

12.Check the ignition coil/flywheel pickup gap (0.4mm max), remove the plastic panel where the pull start goes, you will see the fly wheel and close by, the ignition coil, the part close to the flywheel is where the ignition pulse is picked up, check the gap between the flywheel and the pickup, you can adjust it with Allen keys or torx keys on the coil, don't set it so the pickup scuffs the fly wheel magnet, rotate the fly wheel whilst setting the gap (the flywheel has a magnet in it). Use a feeler gauge.

13. Fit a clean spark plug and check the gap (0.5-0.6mm), Use the correct spark plug. It's worth trying a very slightly larger electrode gap (your local motorcycle guys will tell you, it's to do with your local fuel and Altitude. Learn to "read" spark plug electrode colouring you want "biscuit brown", it's the best way to check your combustion is right. Oil around the spark plug means its not sealing properly (low compression), don't over-tighten the spark plug, rather replace it with a new one with a new seal washer, if possible fit using a torque wrench. Don't underestimate the importance of the right spark plug and electrode gap, it really does make a huge difference to the performance of the engine.

14. Make sure your exhaust is well sealed and clean and the securing screws are tight.

15. Check your fuel filter is clean and working

16. Check your throttle cable is ok and does not have too much slack in it, (adjust at handle bar), same for the on/off choke control cable, check its set up correctly, when in the engine off position at the handle bar control, the spring on the carb rod should not pull up more than 1 mm above the plunger top position. On my bike, the throttle twist required to get maximum revs is only about 1/2 of the total rotational range of the control. I have put tape markers on my twist throttle control to see where I tend to twist it. Make sure the choke slides fully up and down inside the carb (remove the air filter and look into the carb, on full choke, the slide (with hole in it) should be fully down, and with choke off, the slide should be fully clear of the carb induction port the slide range is set by a circlip on the black plastic choke control plunger)

17. Riding, when starting, take 2-5 minutes to warm the engine up by riding slowly on the flat, always pedal to start off to avoid staining the clutch.

18. Riding, when the road is bumpy take your weight off the saddle and stand on the pedals with your knees slightly bent, to reduce the shocks to the rear of the bike. Never ride over pot holes at high speed, remember your cast alloy back wheel won't straighten out once bent. I have found that sometimes if I hit a hard bump, the engine dies a little, I think this is due to a fuel-splashing disturbance in the carb, it take a few minutes further riding slowly to get full power out of the engine again.

19. Riding, Air resistance becomes significant above 15 km/hr, reduce your profile by crouching towards the handle bars and (if you, like me have a women's bike) rest your feet on the cross bar.

19. Take basic tools and spares with you!.

20. Check your transmission oil, use the right one.

21. It has been suggested to drill more air holes into the induction port muffler box (black plastic box and lid), I have found that this box is an important part of the air-flow design of the carb, I found that if I remove the lid whilst the engine is running at idle, the engine slowly stops due to overly lean idle mixture, this can lead to over-heating and temporary loss of compression and difficult starting.

22. Reduce your bike's weight, remove unused parts (I removed the clear plastic side guards below the parcel rack on mine, because they resonate with the engine vibration and make a terrible noise!)

23. Starting, if you are finding your machine difficult to start, remember - Fuel, Ignition, Compression, and Timing., if you are away from home and are really struggling to get the Sachs engine going, try the following procedures.

Choke use

Coke is only needed for starting, do not pull starting cord more than 5 times with choke on as flooding can occur - (you will smell the fuel nearby).

Cold Starting - full choke, pull start until engine starts, run until idle speed starts to drop, then quickly move to half-way between coke and run (1/2 Choke), let engine idle for a few seconds, when idle speed starts to drop again set to run position and rev the engine a little to stabilise warm up.

Cool start (engine stopped between 5-20 mins), two pulls on run position, then two pulls on choke, then pull again on run position, should start ok.

Warm start - (engine off for less than 5-10 mins) pull on run position only unless its not starting, give on pull on coke, then pull start on run, if it starts on choke, set run position as soon as the engine is running and idle speed is dropping.

More choke is needed starting in cold weather.

Over heating can occur if you run the engine at idle with the plastic back cover removed, the engine will slowly die and may overheat, this will result in the engine being difficult to start for 10 mins due to low compression (feel low compression when pulling the starting cord). Just let it cool down for 10 mins and do a cool start

If you suspect a flooded engine (too much choke used, or bumpy riding) let the machine stand for 5 mins to allow the fuel to evaporate and try starting again in the "run" position, if it's still tricky, get only one pull with say, half choke.

Trouble starting?

1. Relax, find a quite. Safe place with flat ground and put the bike up on the stand. If you have been riding your machine ok and are finding it difficult to start, I find that nine times out of ten it's a fuel issue (not enough drawn in by not using enough choke, or flooding by using too much!). If you suspect a flooded engine, just wait 5-10 minutes or ride on pedals and try starting again.

2. Check there is fresh uncontaminated (water etc) fuel in the tank, and you can see it in the fuel filter, pipe.

3. If you can remove the spark plug, check there is spark but touching the bottom of the removed plug onto the engine chassis (with the spark plug cable connected to the top of the pug as usual) and gently pulling the starting cord, you should see sparks (avoid pulling the engine start with the spark plug disconnected of the bottom of the plug not grounded (can damage the CDI)

4. Assuming you do have spark, try unscrewing the back air filter box and remove the air filter, block the carb inlet port with a finger and pull the starting cord once or twice slowly. This has a strong choking effect and draws fuel into the carb, (you should see it wet in the inlet when you remove your finger). Replace air filter and try starting again This very often get the engine running especially if the machine has been standing for a while. Check your choke is actually setting right, the bing carb has a control plunger the height of this sets the coke, make sure the curclip on that plunger is set to allow the choke slide to go all the way down.

5. If you don't have spark, its time to check your wiring, inspect the connectors on the CDI and on the coil unit (might have to remove the plastic side panel). Try disconnecting the blue wire that runs into the top of the carb box to the carb, that's the kill switch wire and if the switch in the carb is stuck on, there will never be spark. Note that if you do get the engine running with the kill switch wire disconnected, you will need to touch that wire (from the CDI) to the engine chassis to stop the engine (never pull the spark plug cable off to stop the engine, you might damage the CDI unit). Make sure none of the connectors are shorted out to one another or the engine chassis. If your On/Off/Choke cable is not correctly adjusted you can find that the engine kills when you select the normal running position after starting on choke.

6. If you are finding your carb is flooding and fuel is dripping out, the carb needle valve is fouled and not closing properly, you need to strip down the carb and clean it. Remember to work safely with fuel!

7. If you are not getting any fuel to the carb, check your control cables, it could be the stop cock inside the carb, your pipes, filter etc.

8. If you are finding the pull start much easier to pull and the motor turns a little after you pull, you are loosing compression, check your spark plug is ok and fitted properly (Don't get any dirt or foreign objects in to the cylinder from the spark plug hole!) This can be caused by an over-heating engine, due to overly lean mixture( black plastic lid removed, or blocked jets?)

Quick check list on troublesome starting...

FUEL

1) Fuel, Oil --no fuel, too much oil.

2) Fuel Pipe-blocked.

3) Fuel filter-blocked.

4) Carb stop cock/control cable-damaged, maladjusted.

5) Carb choke slide, plunger/control cable-damaged, maladjusted.

6) Carb needle valve - fouled, damaged, blocked

7) Carb jets- fouled, damaged, blocked

8) Blocked air filter

9) Flooding carb - Fouled needle valve

IGNITION

1) CDI wiring/connectors - connected wrong, disconnected, damaged CDI (check with meter).

2) Ignition coil/pickup/connectors-damaged coil, wires, loose screws on coil (check with meter).

3) Spark plug/cable/connector - Fouled, damaged plug, damaged cable or connector

4) Carb Kill switch-stuck in Kill position inside carb, wire shorted to chassis, control plunger.

COMPRESSION

1) The compression can be lost by over-heating the engine , this is caused by over-lean mixture, let the engine cool. Spark plug (Loose fit, gas escaping) ( make sure plug hole rim is clean, tighten plug with a torque wrench)

2) Cylinder Gaskets, seals.

TIMING

1) Coil gap/flywheel - loose coil mounting, damaged flywheel, coil

2) CDI UNIT-Damaged CDI, wires

3) Reed valves

Modifying the Red Motoplat CDI for Sachs 301/a for unrestricted engine running

The cost of replacing a destroyed CDI is quite high, so I recommend that this is undertaken with the view that you won't be annoyed if you do destroy the unit. The best approach is to take the time to build yourself a basic replacement CDI (see links) , fit and run your bike with that unit for a while before attempting to modify the Motoplaat unit. That way, if you do destroy the stock CDI, you can still ride on your homemade one!

There are a few comments and pictures on the internet suggesting it is possible to drill a hole into a stock CDI unit, apparently, if done in the correct location the speed restriction can be removed! This is a completely crazy idea, I do not advise you try just drilling holes in your CDI, you will destroy it and feel like an idiot, for the rest of the day.

? Don't drill holes!

See the links for the do it yourself CDI, which I built and fitted to my Sachs 301, it works well and for me I did use the extra delay circuit to get better timing with my machine. I fitted the LC delay circuit with a wire link option to run with or without and found better performance with the delay connected - I am sure that the so-called "chip-tuning" aftermarket CDI units sold in Holland and Germany are the same as the simple circuits in road-runners page!

The reason I decided to look at modifying my red Motoplat CDI, was that I am sure that there is some advance/retard operation going on in that unit which that home-made version does not offer.

I have found that the idling performance is slightly better with the modified red Motoplat than with the road-runner circuit.

I say it's a modification, really it's an adjustment.

You will need a grinder, and sharp Scalpel NTcutter/Stanley knife and 45 mins free time for the job, not less. A good light and magnifying glass will help.

First grind the red plastic off the side and top of the CDI (check the photo you are doing the right side!) Don't grind the circuit board, only the outer plastic and resin areas.

Using a blade, CAREFULLY slice away the resin, layer-by-layer, rather go too slow, than in a hurry.

If you dig too deep, too fast, you could easily cut a capacitor and destroy the unit

When you get close to the blue trim pots, go very slowly, using a tiny blade and needles pick out all the resin from the trim pot white slot, don't be tempted to try and turn the trim pots before you have cleaned away all the resin, the white trim pot plastic is soft, be careful not to cut it. You will need to cut and loosen the resin behind the trim pots as well so you don't rip them out when you turn them. If you hit metal whilst cutting away the resin, avoid that area, it's one of the capacitors!

When you're ready, insert a trimmer or small screwdriver and VERY GENTLY apply turning pressure in both clock-wise and anti-clockwise directions on the trim pots.

Make a note of the trim pot positions.

When you get them loose, very slowly turn the trimmers in each direction a small way, (don't force them they have an end-point), getting further and further round until you can easily turn them both through their whole range, then return the trim pots to the original positions and clean up your CDI.

The engine speed limit control is on the Trim pot marked 2k or 2k5, nearest the metal contacts on the CDI, all you need to do know is turn that one fully anticlock-wise to its end-stop position ( about 7 o'clock).

Refit the unit and go ride, (start slow and warm the engine before , take your tools and home-made CDI as a spare) you should be getting 29-30 km/hr on the flat no wind with good spark plug and carb, anything over 25km/hr on the flat shows that the restriction is off.

Carry your home-made CDI with you and make some comparison tests.

Re-seal your "adjusted" CDI with a glue gun to avoid dirt going into the exposed trim pots.

I have not tried changing the other trim pot (200e, 200 ohm); I think it is for the spark delay, period, current. So at the point, I recommend you leave it as it is, or experiment and let me know how your do.

To summarise; for speed you need.....

1> Free-running true wheels

2> Pumped tyres

3> Correct fuel/oil

4> Modified CDI, correct flywheel/coil pick up gap setting

5> Correct spark plug and gap setting

6> Clean carburettor and air filter

7> Flat smooth road, no wind, low-drag riding position and clothing.

With all these conditions you should get a steady 28 - 30 km/hr drive on your Sachs 301/a 26x1 3/8 wheel machine.

Ignition electrical tests

1) Use an analogue multimeter so you can see the ignition pulses

Test for resistance:......

2) Test Spark plug Resistance from top to electode - 1ohm or less

3) Test Spark plug connector to chassis resistance - 4000 ohms (4K)

4) Test Spark plug connector to red coil wire (CDI output) resistance - 4000 ohms (4K)

5) Test Spark plug connector to Blue coil wire (CDI intput) resistance - 4000 ohms (4K)

6) Test Coil Pulser wire (Blue) to chassis - 110,000 ohm (110K)

7) Test Coil Trigger wire (Red) to chassis - <1ohm

8) Test Coil Trigger wire (Red) to Pulser wire (Blue) - 110 ohm

9) Using AC volts on your meter set to up to 10 VAC, Test output when cranking engine with CDI, sparkplug and kill switch removed/disconnected - You should see the meter pulse 3-5 VAC on the blue wire, (CDI input from pulser coil). I cannot read the CDI output pulses with my multi-meter, I suspect the pusles are too short to move my meter, maybe try a neon bulb between the red wire and chassis - you may be able to see the neon flash as the CDI output pulses (don't forget to keep the red wire connected to the coil whilst doing this test).

10) Check CDI resistances

Pos=Bluetag,Neg=redtag - 100k ohm.

pos=redteg,Neg=bluetag - 25K ohm.

pos=bluetag,Neg=Earthtag - 100k ohm.

pos=Earthtag,Neg=bluetag - 20k ohm.

pos=redtag,Neg=Earthtag - 2k ohm.

pos=Earthtag,Neg=Redtag - 2k ohm.

Last edited by a moderator: