Howzit Everyone,

Making your own Copper Head Gaskets saves a lot of money$ and now you can match the combustion chamber exact.

Cutting and drilling thin copper sheet takes some thought and skill. I'll explain in order what works for me and the basic tools I use.

I use .016 th" thick copper sheet and sandwich the copper sheet between two pieces of wood. I make 3 at a time.

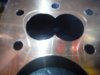

Using an old gasket line it up and mark center of cylinder on wood. Drill a pilot hole.

Using the correct size hole saw drill the cylinder hole. I use 2 1/4"

Using an old gasket line it up with the cylinder hole just drilled and trace valve area on wood.

Drill out valve area with correct size hole saw. Only get close to the traced line. I use 1 1/8"

Remove copper sheet from the wood. Using an old gasket line it up with copper sheet.

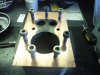

Mark bolt holes and center punch them. Then drill bolt holes in copper sheet.

The best way I've found to do this is to drill two bolt holes first, Front and Rear. I bolt the head and copper sheet to one piece of wood.

Using the head bolt holes as a guide I drill out the rest of the bolt holes in the copper sheet.

Start with the smallest drill bit and work your way up to bolt hole size. Don't press too hard let the drill bit do the work.

Now smear a light coat of grease on the head. Make a pattern by Lining up the copper sheet to the head and make an imprint of the combustion chamber or trace an old gasket. Etch the combustion chamber pattern on the copper sheet with a scratch awe.

Use the Dremel tool with a thin cut off wheel. Cut to line as close as possible without cutting line.

Finish combustion chamber pattern with Dremel tools metal grinding barrel, grinding stone and sanding barrel.

Now make the perimeter pattern. Trace an old gasket perimeter or make an imprint of cylinder deck perimeter on the copper sheet.

Using Dremel tool with a thin cut off wheel cut out the pattern. Clean up edges with Sanding Disc .

Sand with an electric palm sander or sand by hand all burrs with 80 or 120 then 220 sandpaper. The new copper gasket is finished.

I buy my copper sheet from Ace Hardware .016" x 6" x 12" for $12.99 a sheet makes 3 gaskets.

After ya make one or two you'll get the hang of it.

No pictures of making copper gaskets yet. Over the years I've made a whole bunch to match the different heads I have.

I hope this info can help someone

ALOHA Wrench

Making your own Copper Head Gaskets saves a lot of money$ and now you can match the combustion chamber exact.

Cutting and drilling thin copper sheet takes some thought and skill. I'll explain in order what works for me and the basic tools I use.

I use .016 th" thick copper sheet and sandwich the copper sheet between two pieces of wood. I make 3 at a time.

Using an old gasket line it up and mark center of cylinder on wood. Drill a pilot hole.

Using the correct size hole saw drill the cylinder hole. I use 2 1/4"

Using an old gasket line it up with the cylinder hole just drilled and trace valve area on wood.

Drill out valve area with correct size hole saw. Only get close to the traced line. I use 1 1/8"

Remove copper sheet from the wood. Using an old gasket line it up with copper sheet.

Mark bolt holes and center punch them. Then drill bolt holes in copper sheet.

The best way I've found to do this is to drill two bolt holes first, Front and Rear. I bolt the head and copper sheet to one piece of wood.

Using the head bolt holes as a guide I drill out the rest of the bolt holes in the copper sheet.

Start with the smallest drill bit and work your way up to bolt hole size. Don't press too hard let the drill bit do the work.

Now smear a light coat of grease on the head. Make a pattern by Lining up the copper sheet to the head and make an imprint of the combustion chamber or trace an old gasket. Etch the combustion chamber pattern on the copper sheet with a scratch awe.

Use the Dremel tool with a thin cut off wheel. Cut to line as close as possible without cutting line.

Finish combustion chamber pattern with Dremel tools metal grinding barrel, grinding stone and sanding barrel.

Now make the perimeter pattern. Trace an old gasket perimeter or make an imprint of cylinder deck perimeter on the copper sheet.

Using Dremel tool with a thin cut off wheel cut out the pattern. Clean up edges with Sanding Disc .

Sand with an electric palm sander or sand by hand all burrs with 80 or 120 then 220 sandpaper. The new copper gasket is finished.

I buy my copper sheet from Ace Hardware .016" x 6" x 12" for $12.99 a sheet makes 3 gaskets.

After ya make one or two you'll get the hang of it.

No pictures of making copper gaskets yet. Over the years I've made a whole bunch to match the different heads I have.

I hope this info can help someone

ALOHA Wrench

Attachments

-

DSCF8852.JPG155.1 KB · Views: 529

DSCF8852.JPG155.1 KB · Views: 529 -

DSCF8857.JPG169.1 KB · Views: 539

DSCF8857.JPG169.1 KB · Views: 539 -

DSCF8858.JPG157.6 KB · Views: 434

DSCF8858.JPG157.6 KB · Views: 434 -

DSCF8859.JPG106.7 KB · Views: 477

DSCF8859.JPG106.7 KB · Views: 477 -

DSCF8861.JPG151.6 KB · Views: 466

DSCF8861.JPG151.6 KB · Views: 466 -

DSCF8862.JPG104.9 KB · Views: 433

DSCF8862.JPG104.9 KB · Views: 433 -

DSCF7351.JPG171.2 KB · Views: 505

DSCF7351.JPG171.2 KB · Views: 505 -

DSCF8864.JPG147.8 KB · Views: 465

DSCF8864.JPG147.8 KB · Views: 465 -

DSCF8643.JPG150 KB · Views: 456

DSCF8643.JPG150 KB · Views: 456

Last edited: