hey guys !

just started a new project. haven't yet purchased anything as i am still desinging the thing, thinking about the mechanisms, ways to build etc.

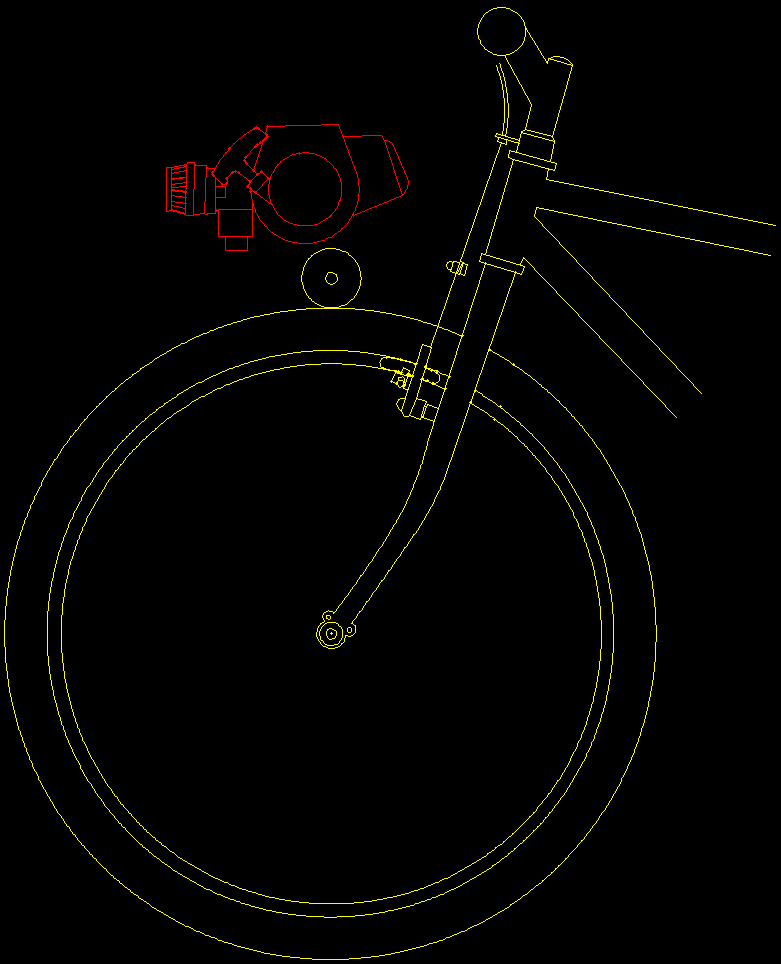

who hasnt been thinking about a better bike kit? not me. i'd like to make a kind of kit that you strap on your bike's fork and just put a pocket bike engine, or make the whole fork with the mounts and mechanism that youd put on your bike.

well thats what i want to build!

my first bike was a 40cc chainsaw rear wheel friction drive.

it was very good on several points:

-simple; just a chainsaw with a friction drive mounted on a plywood mount

-light; the whole motorisation added under 10kg/20lbs to the bike

-still a good bicycle; the engine caused zero friction when not used, unlike a bike kit whitch chain causes drag when pedalling or going down a hill.

-cheap; can buy an old running chainsaw for a reasonable amount of money

-a smooth riding experience; the engine caused virtually no vibrations on the bike

-closer to a bicycle than a motorcycle (less problems with cops)

-downsides-

-a bit loud

-not very reliable (plywood)

-the drive slipped on the tire quite often, causing friction and wear on the tire

-almost impossible to find spares for the chainsaw engine

here, i would fix or improve:

-reliability, with a steel construction;

-noise, whith a homemade quiet muffler;

-friction drive slipping, using a 6:11 chain reduction before the drive shaft, which allows me to use a 60mm/2 3/8" diameter drive instead of 30mm for a larger contact area with the tire;

-the engine would be on top of the wheel instead of on the side

-easy to find spares for the engine and for cheap

-even less problems with cops as it is very close to a Solex (street legal 50cc front wheel friction drive bicycle, made in France a long time ago, that required no helmet, no licence and no insurance until a few years ago, now the law says you to have to get a license plate and an insurance, but cops dont know it and none of those who know says anything if you didnt do it as solexes are rare and people are very nostalgic about those)

-better looking bike

-it is still cheap (pocket bike engine is 55-60euros), light, simple (kinda), and causes no drag when not using the engine.

(designing the bike)

just started a new project. haven't yet purchased anything as i am still desinging the thing, thinking about the mechanisms, ways to build etc.

who hasnt been thinking about a better bike kit? not me. i'd like to make a kind of kit that you strap on your bike's fork and just put a pocket bike engine, or make the whole fork with the mounts and mechanism that youd put on your bike.

well thats what i want to build!

my first bike was a 40cc chainsaw rear wheel friction drive.

it was very good on several points:

-simple; just a chainsaw with a friction drive mounted on a plywood mount

-light; the whole motorisation added under 10kg/20lbs to the bike

-still a good bicycle; the engine caused zero friction when not used, unlike a bike kit whitch chain causes drag when pedalling or going down a hill.

-cheap; can buy an old running chainsaw for a reasonable amount of money

-a smooth riding experience; the engine caused virtually no vibrations on the bike

-closer to a bicycle than a motorcycle (less problems with cops)

-downsides-

-a bit loud

-not very reliable (plywood)

-the drive slipped on the tire quite often, causing friction and wear on the tire

-almost impossible to find spares for the chainsaw engine

here, i would fix or improve:

-reliability, with a steel construction;

-noise, whith a homemade quiet muffler;

-friction drive slipping, using a 6:11 chain reduction before the drive shaft, which allows me to use a 60mm/2 3/8" diameter drive instead of 30mm for a larger contact area with the tire;

-the engine would be on top of the wheel instead of on the side

-easy to find spares for the engine and for cheap

-even less problems with cops as it is very close to a Solex (street legal 50cc front wheel friction drive bicycle, made in France a long time ago, that required no helmet, no licence and no insurance until a few years ago, now the law says you to have to get a license plate and an insurance, but cops dont know it and none of those who know says anything if you didnt do it as solexes are rare and people are very nostalgic about those)

-better looking bike

-it is still cheap (pocket bike engine is 55-60euros), light, simple (kinda), and causes no drag when not using the engine.

(designing the bike)

Last edited: