FurryOnTheInside

In Memoriam

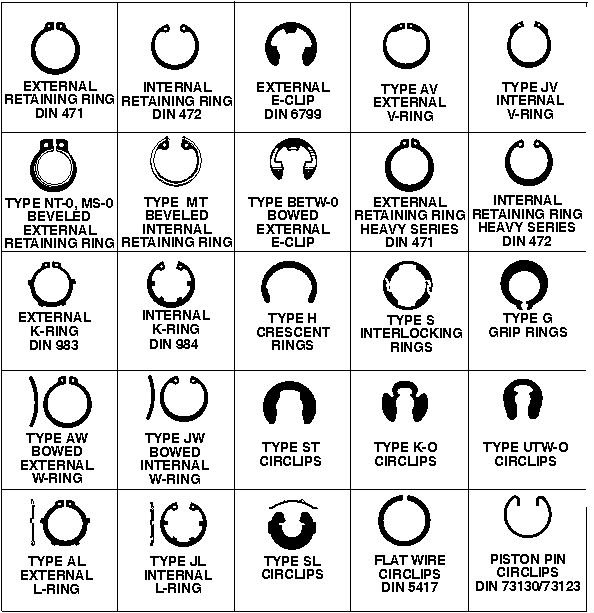

Is it just me and my terrible technique and ineptitude, or is the G shape circlip a total pain in the proverbial? I just don't fancy struggling to get my top end together and then not entirely trusting it.

Would it be a good idea to use the kind with the two little holes for circlip pliers instead? Has anyone done this, or felt any need to?

Looking at the circlips available on the net it sems like no one is using the G shape circlip. Even the last one (bottom right) on this chart actually has two bits to get hold of.

Would it be a good idea to use the kind with the two little holes for circlip pliers instead? Has anyone done this, or felt any need to?

Looking at the circlips available on the net it sems like no one is using the G shape circlip. Even the last one (bottom right) on this chart actually has two bits to get hold of.