45u

Active Member

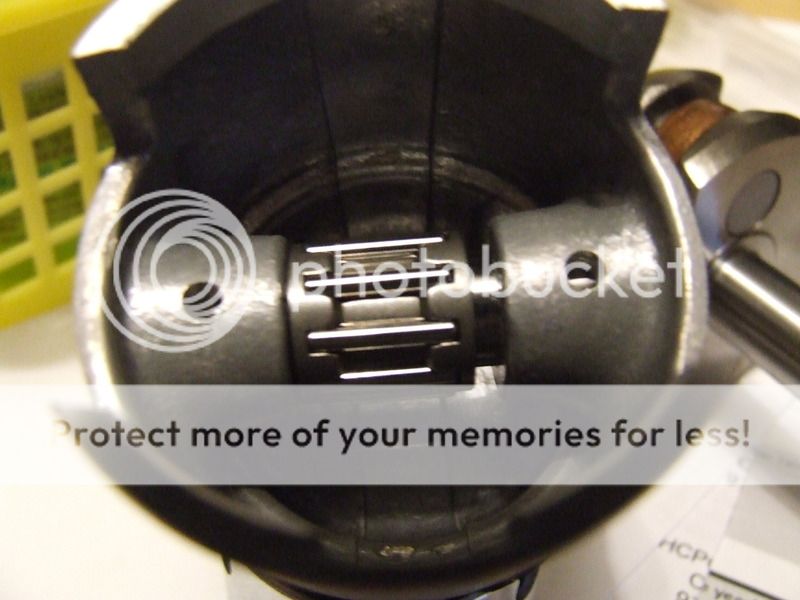

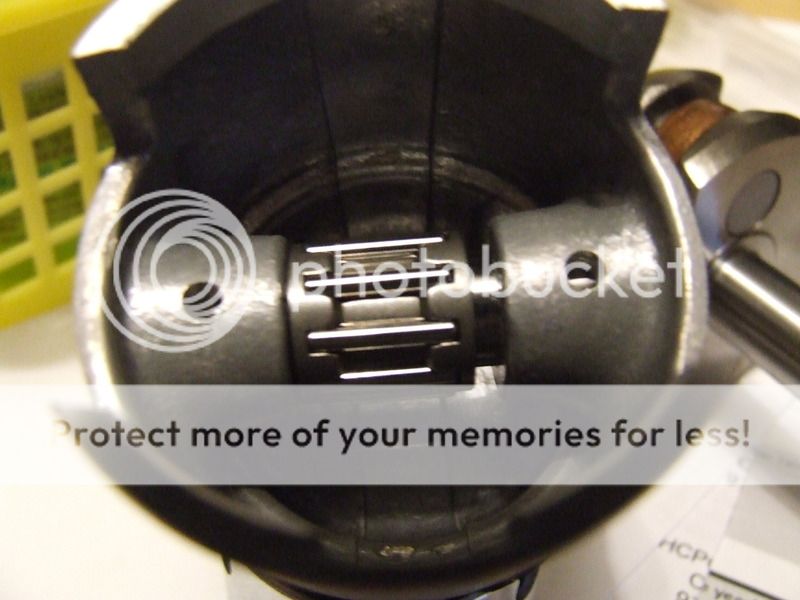

The first and second picture is of a crank and piston out of motors like we run. Notice how much of the bearing load is outside of the top of the rod taking away a good bit of the bearing surface and the bearing is not supporting the rod like it should. This is not good what so ever. All so see how much side to side play the wrist pin bearing has.

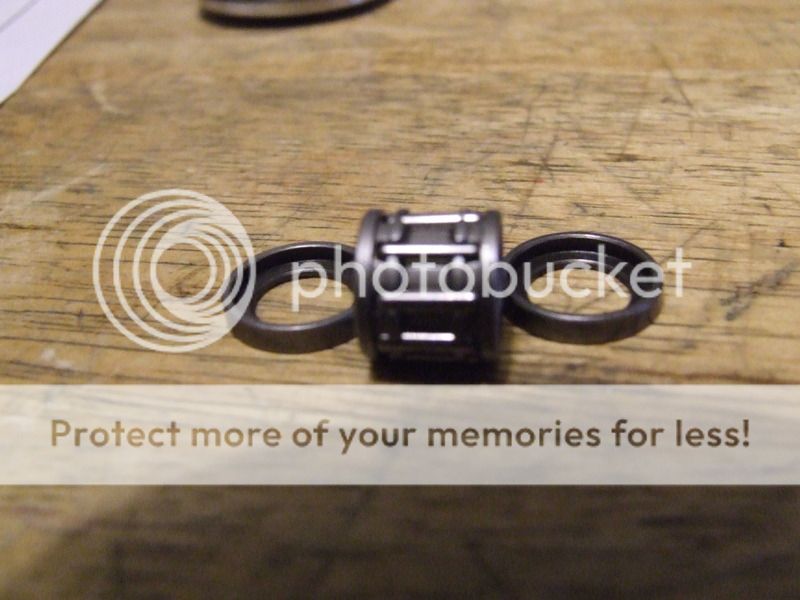

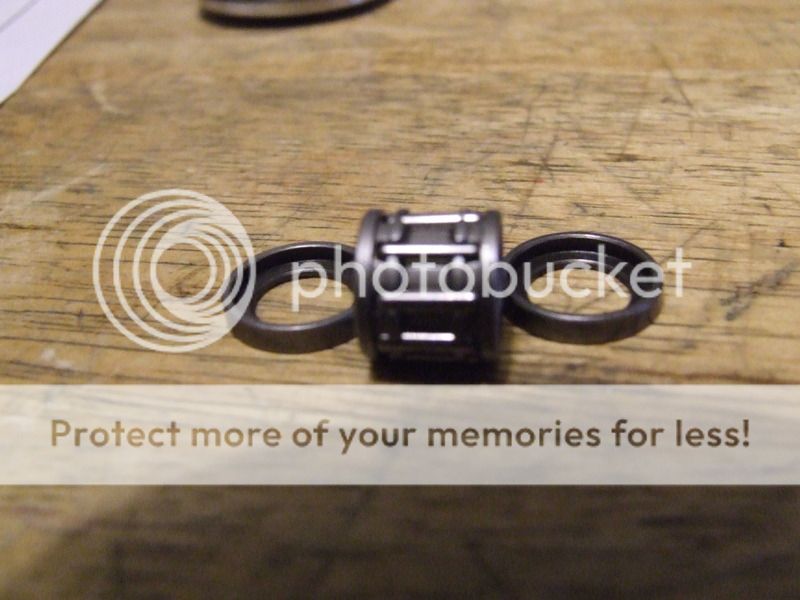

The reaming pictures of some of my radio control 1/5 scale motor parts. Notice the two washers which in close the wrist pin bearing on the ends making it where it does not move side to side much making a much better bearing load and is always very close to center. The upper rod end is supported all the times and the rod is not hanging off one side like on the motors we run. The washers cover the end of the wrist pin bearing where it cannot move side to side much as well as the rod cannot move much. The washers are made flat on one side, piston side and the others has a recues that allow the wrist pin bushing to stay centered much better than the set up on the motors we run. The rod does not fit over the washers. You will see on the RC piston there is still a little play and has to be but the ones we run have way too much side to side play.

Being on the motors we run the bearing load is much of the time on one side of the top rod not giving not near as much of a good bearing load? What do others have to think?

The reaming pictures of some of my radio control 1/5 scale motor parts. Notice the two washers which in close the wrist pin bearing on the ends making it where it does not move side to side much making a much better bearing load and is always very close to center. The upper rod end is supported all the times and the rod is not hanging off one side like on the motors we run. The washers cover the end of the wrist pin bearing where it cannot move side to side much as well as the rod cannot move much. The washers are made flat on one side, piston side and the others has a recues that allow the wrist pin bushing to stay centered much better than the set up on the motors we run. The rod does not fit over the washers. You will see on the RC piston there is still a little play and has to be but the ones we run have way too much side to side play.

Being on the motors we run the bearing load is much of the time on one side of the top rod not giving not near as much of a good bearing load? What do others have to think?