safe

Active Member

- Local time

- 2:51 PM

- Joined

- Mar 28, 2009

- Messages

- 1,319

The Halbach Disc Motor Ebike Project

http://www.motoredbikes.com/showthread.php?t=23955

The theory was developed on the other thread and now I'm going to begin the actual "build" process of the Halbach Disc Motor idea. (after about two months of motor research)

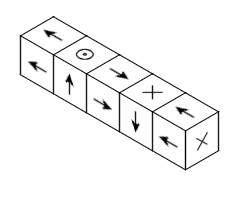

This will NOT be an axial motor.... the magnets will extend their magnetism radially away from the rear wheels hub center. Just want to be sure that people understand the concept because most of the Halbach disc-like motors that are standalone (not built into the rear wheel) make use of the axial design and two parallel discs surrounding the third which is the rotor that holds the copper magnet wires.

In this design there is just ONE DISC and it has a Halbach array facing radially outwards from it's circumference and the magnet wires will be on a stationary device that will resemble something like a brake disc caliper.

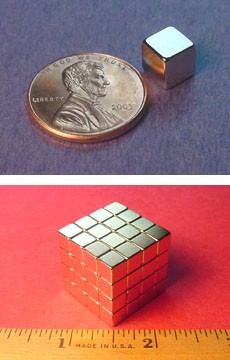

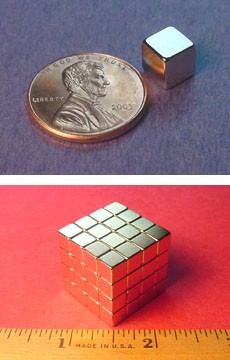

Here are the components that I will begin with:

...looks like tomorrow might be warm enough to do some work on this.

http://www.motoredbikes.com/showthread.php?t=23955

The theory was developed on the other thread and now I'm going to begin the actual "build" process of the Halbach Disc Motor idea. (after about two months of motor research)

This will NOT be an axial motor.... the magnets will extend their magnetism radially away from the rear wheels hub center. Just want to be sure that people understand the concept because most of the Halbach disc-like motors that are standalone (not built into the rear wheel) make use of the axial design and two parallel discs surrounding the third which is the rotor that holds the copper magnet wires.

In this design there is just ONE DISC and it has a Halbach array facing radially outwards from it's circumference and the magnet wires will be on a stationary device that will resemble something like a brake disc caliper.

Here are the components that I will begin with:

...looks like tomorrow might be warm enough to do some work on this.

Attachments

Last edited: