Marine One

Member

- Local time

- 8:18 PM

- Joined

- Apr 18, 2016

- Messages

- 44

Hello all and great site yall have. Long time lurker, first time poster.

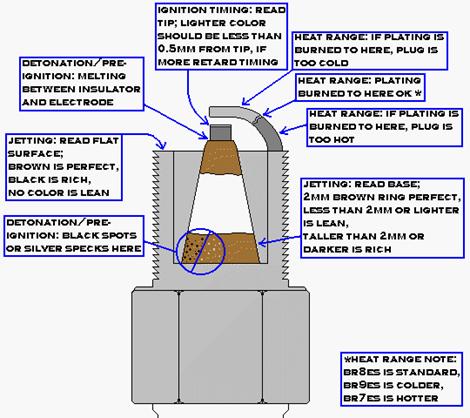

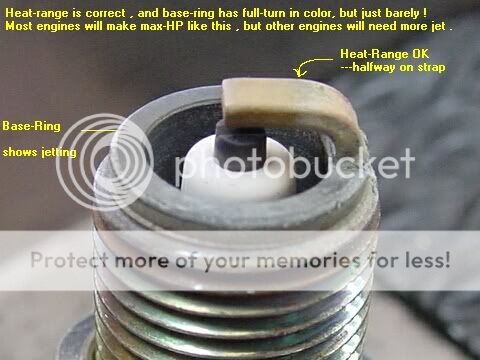

I recently bought my first 66/80 cc motorized bike, it came with 1 spare engine and most of the parts for another kit. The bike had a large crack in the frame near the bottom where you pedal but I already had a better bike for the transplant. Anyhow. The motor runs fine and starts up without a hiccup except when its cold (I have to pedal a little longer, no big deal) but my big problem is that it knocks on the high end. I have a 36T sprocket and I just put a speedometer that is calibrated for my 29" rims and I am hitting about 20-25 normal with a top speed of 29.1 registered on it. I don't know what kind of RPM's I am actually running because I don't have a tachometer yet. I have the stock NT carb it looks like. When the knocking starts it robs a LOT of power and it stops accelerating and actually decelerates a little. I can tell that it really wants to give more but its just cant for some reason. Under reasonable load it seems to work much better but once I hit a downhill or get up enough speed on a flat stretch is when it really happens. The chain isn't hitting anything, I have a fairly heavy duty spring tensioner on it. I don't ride the bike for long periods of time, typically 20 minutes or less.

Wondering if it is because the ignition is firing too soon and I need to get a CDI with a delay at the top end or maybe its not balanced and there is too much play in the bearing at the piston, but if it was the bearing wouldn't it do it all the time?

Keep in mind that I have no idea how old this motor is, what brand it is, or what the old owner put it through before he sold it. He probably weighed about 250 but we live near the beach so its pretty flat.

Trying to include everything I think might help but I'm sure that I left something out. Any help would be Greatly appreciated. Thank you and Semper Fi.

I recently bought my first 66/80 cc motorized bike, it came with 1 spare engine and most of the parts for another kit. The bike had a large crack in the frame near the bottom where you pedal but I already had a better bike for the transplant. Anyhow. The motor runs fine and starts up without a hiccup except when its cold (I have to pedal a little longer, no big deal) but my big problem is that it knocks on the high end. I have a 36T sprocket and I just put a speedometer that is calibrated for my 29" rims and I am hitting about 20-25 normal with a top speed of 29.1 registered on it. I don't know what kind of RPM's I am actually running because I don't have a tachometer yet. I have the stock NT carb it looks like. When the knocking starts it robs a LOT of power and it stops accelerating and actually decelerates a little. I can tell that it really wants to give more but its just cant for some reason. Under reasonable load it seems to work much better but once I hit a downhill or get up enough speed on a flat stretch is when it really happens. The chain isn't hitting anything, I have a fairly heavy duty spring tensioner on it. I don't ride the bike for long periods of time, typically 20 minutes or less.

Wondering if it is because the ignition is firing too soon and I need to get a CDI with a delay at the top end or maybe its not balanced and there is too much play in the bearing at the piston, but if it was the bearing wouldn't it do it all the time?

Keep in mind that I have no idea how old this motor is, what brand it is, or what the old owner put it through before he sold it. He probably weighed about 250 but we live near the beach so its pretty flat.

Trying to include everything I think might help but I'm sure that I left something out. Any help would be Greatly appreciated. Thank you and Semper Fi.