FNTPuck

Well-Known Member

- Local time

- 1:47 AM

- Joined

- Jul 2, 2018

- Messages

- 855

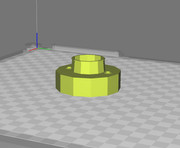

Was bored yesterday and saw the 30mm cone filter from the Keihin clone I purchased lying around and wanted to use it on the stock NT carb, but didn't want to spend the $20 and wait for the velocity stack adapters. I fired up sketchup instead, and started making some prototype adapters 3d printed out of PETG, which is a hard plastic with high heat resistance that doesn't soften much until ~140-150c, which is almost 300*F so should be fine for the intake side of a bike (print temp is 235c). It is a bit brittle though compared to something like bridge nylon, so I printed with 100% infill but may need to eventually add some gussets and reinforcements - my guess is the weak point will be right where the base meets the tube for the filter attachment due to the weight of filter and vibrations, but that will be easy to reinforce if needed.

First print was just to test the dimensions of the mounting area, but I thought it may make a good low profile filter so I threw it together and tested it. It uses the stock hardware, filter, and retention screen but I wasn't expecting to actually use it so it doesn't have the notches for the retention screen. To make it fit and prevent the filter from getting sucked against the carb I just used an xacto to cut them off and make it round. It is 40% thinner, and doesn't have the ~1/2" protrusions coming off the bottom so tons of room even with the stock non-offset intake.

Test bike setup is a stock 66cc with CNC head, supercharge CDI, NGK plug @ .025, two ~1/4" holes drilled across muffler baffle tube (one on top one on bottom of the center tube, plates untouched) and a 39t rear sprocket on a heavy Huffy Fairmont cruiser. Motor is brand new with less than 5 miles on it, so nowhere near broken in, and using 16:1 break-in ratio. Carb is all stock with needle on 2nd from top notch.

Note that much of this testing is subjective and not super scientific - I am just using a cell phone GPS app and doing 2x identical laps around my neighborhood and comparing top speed but I'm not using decimals so its not super accurate. Route has one short downhill, one long uphill, and one long straight so its a great test lap. Also, things like idle quality and smoothness are hard to quantify but I am trying to be as accurate as possible.

Stock filter with "NT" circle logo drilled out to help it breathe(+trimmed braces that block intake on retention screen, as pictured):

31mph, idle was properly dialed in after warm up. Noticably soft low end but stock jetting is pretty close, not lean or rich. (New motor, 39t sprocket, heavy bike, break-in fuel, etc is likely why low end is weak. I'm used to 41t or 44t sprockets and this is my first 39t).

Low Profile(click for big pics):

Same 31mph, idle is higher without touching anything so it definitely flows better at least down low. Mid range is cleaner, seems to rev better. Top end felt better and I got excited but GPS said otherwise...same exact top speed. I'm guessing top speed is the same since the stock filter media pushed up against the carb intake is probably the restriction now instead of the housing itself...or maybe drilling out the NT logo on the stock housing increased airflow over stock enough to limit the difference this much larger intake hole makes. Dont have a stock sealed one to test but may go back to the stocker with that hole taped up to add to results for a true bone stock filter comparison.

Next test will be the full design print with the cone filter attached and the intake extended ~2" and to the side to clear. I'm gonna make the design a bit smaller diameter with a slight overhang to not have to use stock retaining screen. Will hopefully update later today depending on how much time I have to work on it.

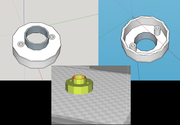

Unfinished model for the cone filter adapter:

First print was just to test the dimensions of the mounting area, but I thought it may make a good low profile filter so I threw it together and tested it. It uses the stock hardware, filter, and retention screen but I wasn't expecting to actually use it so it doesn't have the notches for the retention screen. To make it fit and prevent the filter from getting sucked against the carb I just used an xacto to cut them off and make it round. It is 40% thinner, and doesn't have the ~1/2" protrusions coming off the bottom so tons of room even with the stock non-offset intake.

Test bike setup is a stock 66cc with CNC head, supercharge CDI, NGK plug @ .025, two ~1/4" holes drilled across muffler baffle tube (one on top one on bottom of the center tube, plates untouched) and a 39t rear sprocket on a heavy Huffy Fairmont cruiser. Motor is brand new with less than 5 miles on it, so nowhere near broken in, and using 16:1 break-in ratio. Carb is all stock with needle on 2nd from top notch.

Note that much of this testing is subjective and not super scientific - I am just using a cell phone GPS app and doing 2x identical laps around my neighborhood and comparing top speed but I'm not using decimals so its not super accurate. Route has one short downhill, one long uphill, and one long straight so its a great test lap. Also, things like idle quality and smoothness are hard to quantify but I am trying to be as accurate as possible.

Stock filter with "NT" circle logo drilled out to help it breathe(+trimmed braces that block intake on retention screen, as pictured):

31mph, idle was properly dialed in after warm up. Noticably soft low end but stock jetting is pretty close, not lean or rich. (New motor, 39t sprocket, heavy bike, break-in fuel, etc is likely why low end is weak. I'm used to 41t or 44t sprockets and this is my first 39t).

Low Profile(click for big pics):

Same 31mph, idle is higher without touching anything so it definitely flows better at least down low. Mid range is cleaner, seems to rev better. Top end felt better and I got excited but GPS said otherwise...same exact top speed. I'm guessing top speed is the same since the stock filter media pushed up against the carb intake is probably the restriction now instead of the housing itself...or maybe drilling out the NT logo on the stock housing increased airflow over stock enough to limit the difference this much larger intake hole makes. Dont have a stock sealed one to test but may go back to the stocker with that hole taped up to add to results for a true bone stock filter comparison.

Next test will be the full design print with the cone filter attached and the intake extended ~2" and to the side to clear. I'm gonna make the design a bit smaller diameter with a slight overhang to not have to use stock retaining screen. Will hopefully update later today depending on how much time I have to work on it.

Unfinished model for the cone filter adapter:

Last edited: