AussieSteve

Active Member

A few basics on the Happytime NT Carburetor:-

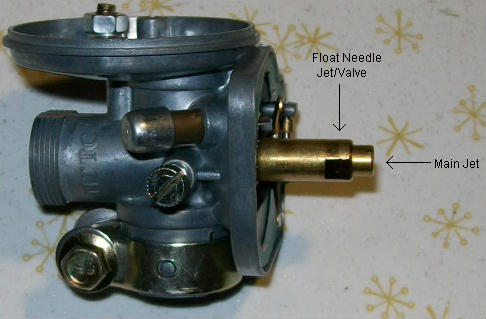

Some pics identifying the basic parts:-

Float Bowl Gasket

Also see srdavo's NT Carburetor Assembly Pics for a bit more info.

Brief Description Of Operation

The NT side-draught carburetor operates by drawing air into the air inlet past the slide needle jet. 'Venturi' action draws fuel from the float bowl upwards into the in-going airstream.

The slide regulates the flow of air into the engine. A slide needle extends below the slide into the slide needle jet to regulate fuel flow during low to about ¾ throttle openings. When the throttle is opened further, from ¾ to full throttle, the 'main jet', screwed into the bottom of the slide needle jet, regulates fuel flow. The slide needle is adjustable, up/down, to increase, (enrich), or reduce, (lean out), the amount of fuel in the mid-range mixture. To adjust ¾ to full throttle mixture, the size of the main jet must be changed, by replacement usually, although drilling or soldering and drilling is an alternative. Larger = richer and vice versa.

There is no idle circuit, pilot jet or idle mixture screw on these carburetors. The slide needle setting also controls the idle mixture.

Specifications

Specs vary with individual carbs and suppliers.

For a 66cc engine, I've heard of stock main jets sized at 0.6mm,(MBB Imports), 0.7mm,(Many US kits) and 0.79mm, (ZBox 66cc).

In the end, many seem to run well on about an 0.72 to 0.73mm main jet, with standard exhaust and porting.

Bore diameter: 14mm.

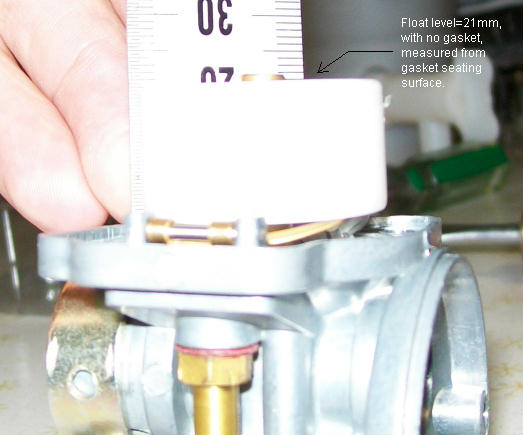

Float level: 21mm.

Tuning

The NT carb supplied with most typical HT engine kits is very simple and so should be easy to tune, but many have trouble getting it right, resulting in low power, low revs, smoky exhausts, fouled plugs and excessive buildup on heads/pistons if the mixture is over-rich or, in the other extreme, overheating, melted pistons, seized engines if the mixture is (way) too lean.

The most common problem is a lean mixture due to an air leak where the carburetor attaches to the inlet tube or where the inlet tube attaches to the cylinder.

The second most common problem is a rich mixture, (usually after sealing the inlet leaks), resulting in four-stroking and reduced power output, often in both the mid-throttle openings and at full throttle. See 'Four-Stroking', in 'Diagnostics' below.

N.B. Before attempting any carby adjustments, ensure that the carb to inlet joint is well sealed, the inlet gasket is in good condition, the carb is clean, the fuel filter and air filter aren't blocked and that the inlet tube nuts are tight.

Adjustments

There is only one direct method of mixture adjustment on these carburetors. This affects low to ¾ throttle openings. The slide needle has a series of notches near the top, (four on earlier carbs and five on the later ones), so that the attached 'C' clip can be removed and refitted to raise or lower the needle relative to the slide and slide needle valve.

When the needle is set lower, relative to the slide, less fuel is allowed into the mixture for a given amount of air, making the mix leaner and vice versa.

To adjust the mixture at ¾ to full throttle openings, the size of the main jet needs to be changed, smaller for a leaner mixture or larger to make it richer.

Diagnostics

One of the best ways to check the mixture is by doing a 'plug chop'. In effect, the engine is first warmed up to operating temperature, then a new plug fitted. Run the engine at the throttle opening for the area of concern for a bit.

ie. Slide needle setting - about ½ throttle.

Main jet - full throttle.

Now, without changing throttle opening, pull in the clutch, hit the kill switch at the same time and roll to a stop.

Check the plug color. If it's tan, the mixture in that range is OK. If black and/or wet, the mixture is too rich. If the plug is grey or whitish the mixture is too lean.

I had thought about including pics of plugs, but don't have any that aren't tan, right now.

One of the more common signs of a rich mixture is 'Four Stroking'. This occurs when the fuel/air mixture is so rich that the engine only gets enough air to fire every second revolution, reducing power and making the engine sound like it is only doing half as many RPM. An overly smoky exhaust is another indication that the mixture may be too rich.

An example of 'Four Stroking', (thanks Al.Fisherman, for pointing it out):-

Four Stroking (YouTube)

Any corrections or other suggestions?

(If this has been useful, please give it a rating.)

... Steve

Some pics identifying the basic parts:-

Float Bowl Gasket

Also see srdavo's NT Carburetor Assembly Pics for a bit more info.

Brief Description Of Operation

The NT side-draught carburetor operates by drawing air into the air inlet past the slide needle jet. 'Venturi' action draws fuel from the float bowl upwards into the in-going airstream.

The slide regulates the flow of air into the engine. A slide needle extends below the slide into the slide needle jet to regulate fuel flow during low to about ¾ throttle openings. When the throttle is opened further, from ¾ to full throttle, the 'main jet', screwed into the bottom of the slide needle jet, regulates fuel flow. The slide needle is adjustable, up/down, to increase, (enrich), or reduce, (lean out), the amount of fuel in the mid-range mixture. To adjust ¾ to full throttle mixture, the size of the main jet must be changed, by replacement usually, although drilling or soldering and drilling is an alternative. Larger = richer and vice versa.

There is no idle circuit, pilot jet or idle mixture screw on these carburetors. The slide needle setting also controls the idle mixture.

Specifications

Specs vary with individual carbs and suppliers.

For a 66cc engine, I've heard of stock main jets sized at 0.6mm,(MBB Imports), 0.7mm,(Many US kits) and 0.79mm, (ZBox 66cc).

In the end, many seem to run well on about an 0.72 to 0.73mm main jet, with standard exhaust and porting.

Bore diameter: 14mm.

Float level: 21mm.

Tuning

The NT carb supplied with most typical HT engine kits is very simple and so should be easy to tune, but many have trouble getting it right, resulting in low power, low revs, smoky exhausts, fouled plugs and excessive buildup on heads/pistons if the mixture is over-rich or, in the other extreme, overheating, melted pistons, seized engines if the mixture is (way) too lean.

The most common problem is a lean mixture due to an air leak where the carburetor attaches to the inlet tube or where the inlet tube attaches to the cylinder.

The second most common problem is a rich mixture, (usually after sealing the inlet leaks), resulting in four-stroking and reduced power output, often in both the mid-throttle openings and at full throttle. See 'Four-Stroking', in 'Diagnostics' below.

N.B. Before attempting any carby adjustments, ensure that the carb to inlet joint is well sealed, the inlet gasket is in good condition, the carb is clean, the fuel filter and air filter aren't blocked and that the inlet tube nuts are tight.

Adjustments

There is only one direct method of mixture adjustment on these carburetors. This affects low to ¾ throttle openings. The slide needle has a series of notches near the top, (four on earlier carbs and five on the later ones), so that the attached 'C' clip can be removed and refitted to raise or lower the needle relative to the slide and slide needle valve.

When the needle is set lower, relative to the slide, less fuel is allowed into the mixture for a given amount of air, making the mix leaner and vice versa.

To adjust the mixture at ¾ to full throttle openings, the size of the main jet needs to be changed, smaller for a leaner mixture or larger to make it richer.

Diagnostics

One of the best ways to check the mixture is by doing a 'plug chop'. In effect, the engine is first warmed up to operating temperature, then a new plug fitted. Run the engine at the throttle opening for the area of concern for a bit.

ie. Slide needle setting - about ½ throttle.

Main jet - full throttle.

Now, without changing throttle opening, pull in the clutch, hit the kill switch at the same time and roll to a stop.

Check the plug color. If it's tan, the mixture in that range is OK. If black and/or wet, the mixture is too rich. If the plug is grey or whitish the mixture is too lean.

I had thought about including pics of plugs, but don't have any that aren't tan, right now.

One of the more common signs of a rich mixture is 'Four Stroking'. This occurs when the fuel/air mixture is so rich that the engine only gets enough air to fire every second revolution, reducing power and making the engine sound like it is only doing half as many RPM. An overly smoky exhaust is another indication that the mixture may be too rich.

An example of 'Four Stroking', (thanks Al.Fisherman, for pointing it out):-

Four Stroking (YouTube)

Any corrections or other suggestions?

(If this has been useful, please give it a rating.)

... Steve

Last edited by a moderator: