This build is kinda odd for me. I typically don't start any project with all new parts. Most of my stuff is but with old junk and some new stuff. That's how I picked the screen name.

My last bike (first MB) was fun but had all kinds of problems with the Seeutek. Bearings went, then it broke a ring, next was wrist pin bearing failure that cracked the piston dome and then the final catastrophic lean the took out the entire top end which was caused by a broken carb. The bike itself also had issues with the derailleurs and brakes due to riding in the winter. Needed a repaint as well. Fvck that. This time I'm starting new.

So....

I decided this bike was going to be a single speed cruiser with disc brakes to solve my biggest issues with the bike itself. Hard combo to find. Found the Hyper at Wallmart by chance and it was cheap, real cheap. Comes with coaster brakes. No big deal, I like building rims and this way I can have exactly what I want. Besides the rims The only other things that needed to be changed are the pedals and handle bars. The bars are like 3' wide WTF. With my BMX background platform pedals is all I'll ride. Both of those issues have been taken care of.

For the engine I picked Zeda because a lot of people seem happy with them. Knew I wanted a reed for the power curve and I ended up going overboard and ordering the Zeda 80 case reed and a MZ65 pipe at the same time. Ship date is between 3/14 and 3/21.

Parts acquired so far:

My last bike (first MB) was fun but had all kinds of problems with the Seeutek. Bearings went, then it broke a ring, next was wrist pin bearing failure that cracked the piston dome and then the final catastrophic lean the took out the entire top end which was caused by a broken carb. The bike itself also had issues with the derailleurs and brakes due to riding in the winter. Needed a repaint as well. Fvck that. This time I'm starting new.

So....

I decided this bike was going to be a single speed cruiser with disc brakes to solve my biggest issues with the bike itself. Hard combo to find. Found the Hyper at Wallmart by chance and it was cheap, real cheap. Comes with coaster brakes. No big deal, I like building rims and this way I can have exactly what I want. Besides the rims The only other things that needed to be changed are the pedals and handle bars. The bars are like 3' wide WTF. With my BMX background platform pedals is all I'll ride. Both of those issues have been taken care of.

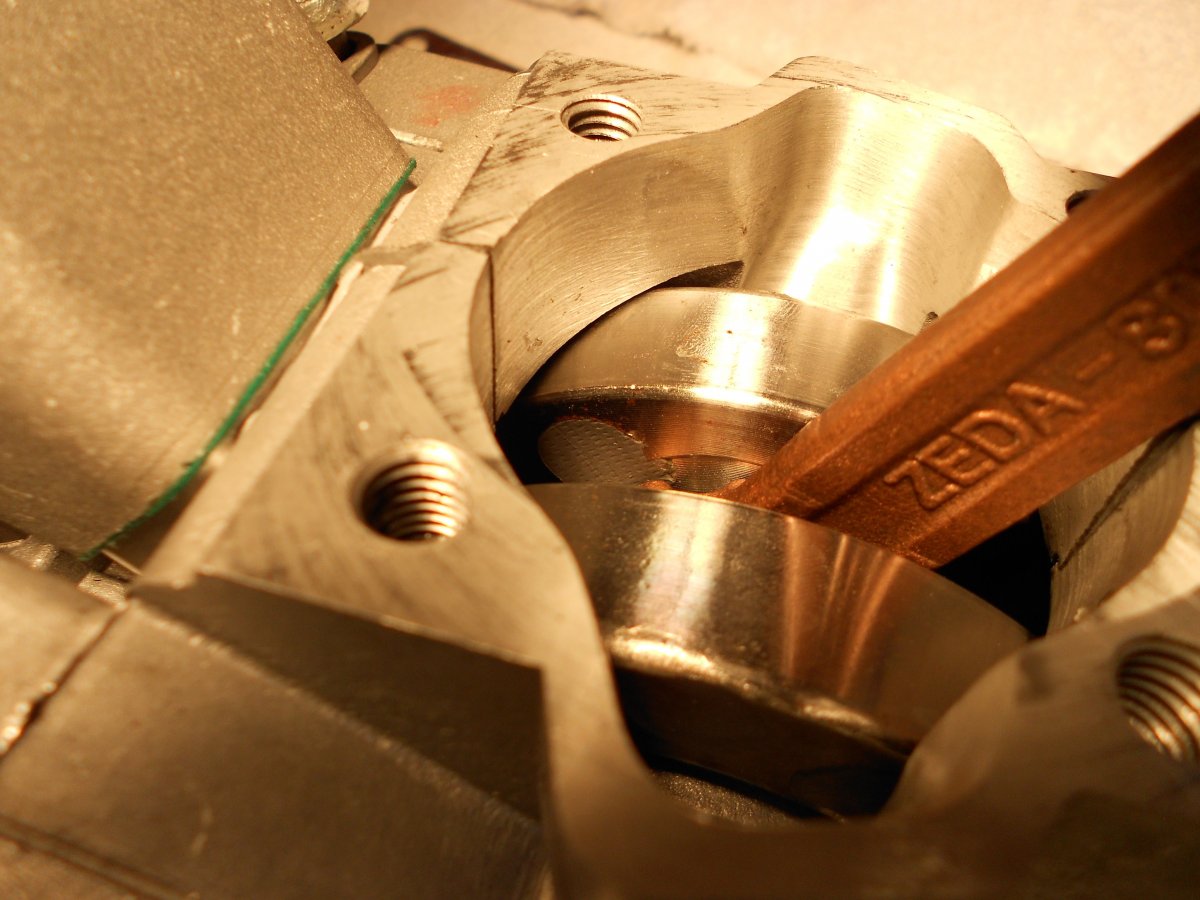

For the engine I picked Zeda because a lot of people seem happy with them. Knew I wanted a reed for the power curve and I ended up going overboard and ordering the Zeda 80 case reed and a MZ65 pipe at the same time. Ship date is between 3/14 and 3/21.

Parts acquired so far:

- Single speed disc hubs

- Disc rotors and calipers

- KMC Z510 chain

- ODI grips

- Dual brake lever

- Matching clutch lever

- Narrow 10 sprocket from BMW

- CNC throttle

- Huffy Davidson Lightning Strike CDI

- Disc Drive sprocket adapter and 410 36t sprocket from MBRebel

- OZ super magneto

- 12g spokes and nipples

- Double wall rims

- Lighting