My motor is finally purchased...i went with the pre sale option at $109 ,delivery im not sure when will take place..This will be somewhat of a slow build as im only expecting to invest so much per month towards the build and im in no hurry anyways..lol

You can find this particular motor and alot more sold through

ZedaMotorsports.com

Expect lots of before and after pics of the build.

Ill start with bottom end and show more as it happens.

So, heres the game plan for the bottom end build...To start, the motor will be taken apart and inspected prior to the changes and thoroughly cleaned.

(Bottom end)

1. Balanced crank (Zeda factory)

2. Lightened rod and pin

4 RB Tech 6202 2RS C3 (ABEC 3) premium crank and clutch bearings.

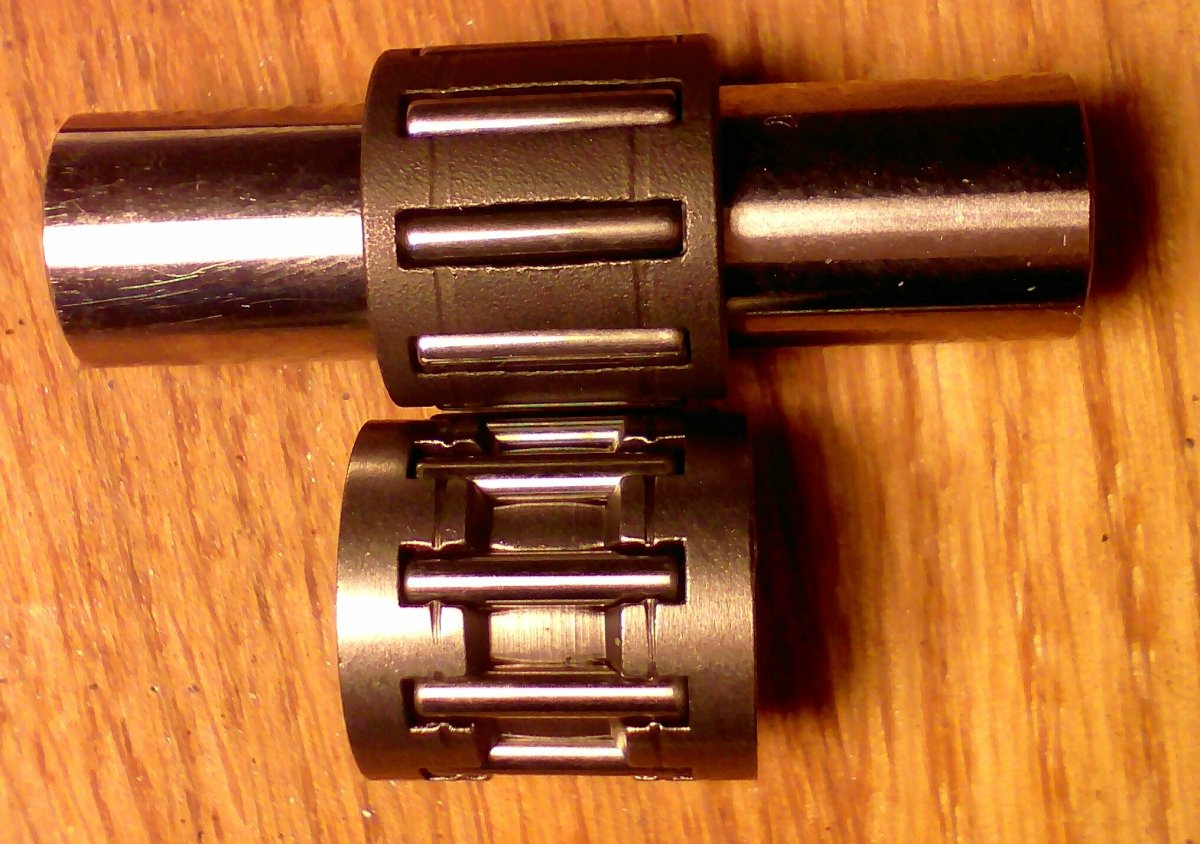

4. Upgrade upper rod bearing.

5. Seal retainer. (comes with motor)

6. Arrow (Red) metallic clutch pads

You can find this particular motor and alot more sold through

ZedaMotorsports.com

Expect lots of before and after pics of the build.

Ill start with bottom end and show more as it happens.

So, heres the game plan for the bottom end build...To start, the motor will be taken apart and inspected prior to the changes and thoroughly cleaned.

(Bottom end)

1. Balanced crank (Zeda factory)

2. Lightened rod and pin

4 RB Tech 6202 2RS C3 (ABEC 3) premium crank and clutch bearings.

4. Upgrade upper rod bearing.

5. Seal retainer. (comes with motor)

6. Arrow (Red) metallic clutch pads

Last edited: