Started the new bike build. Went with the new style Cranbrook and will be doing a ton of mods. Already cut of the stock dropouts and welded on some horizontal dropouts in their place. Working on running the electrical and cables in frame. Shortened the seat tube 1" at the clamp. Plan to add some bracing in a few places. And of course an in frame tank is in the works.

Going to use the case reed again but I'm rebuilding it with some mods and upgrades.

Going to use the case reed again but I'm rebuilding it with some mods and upgrades.

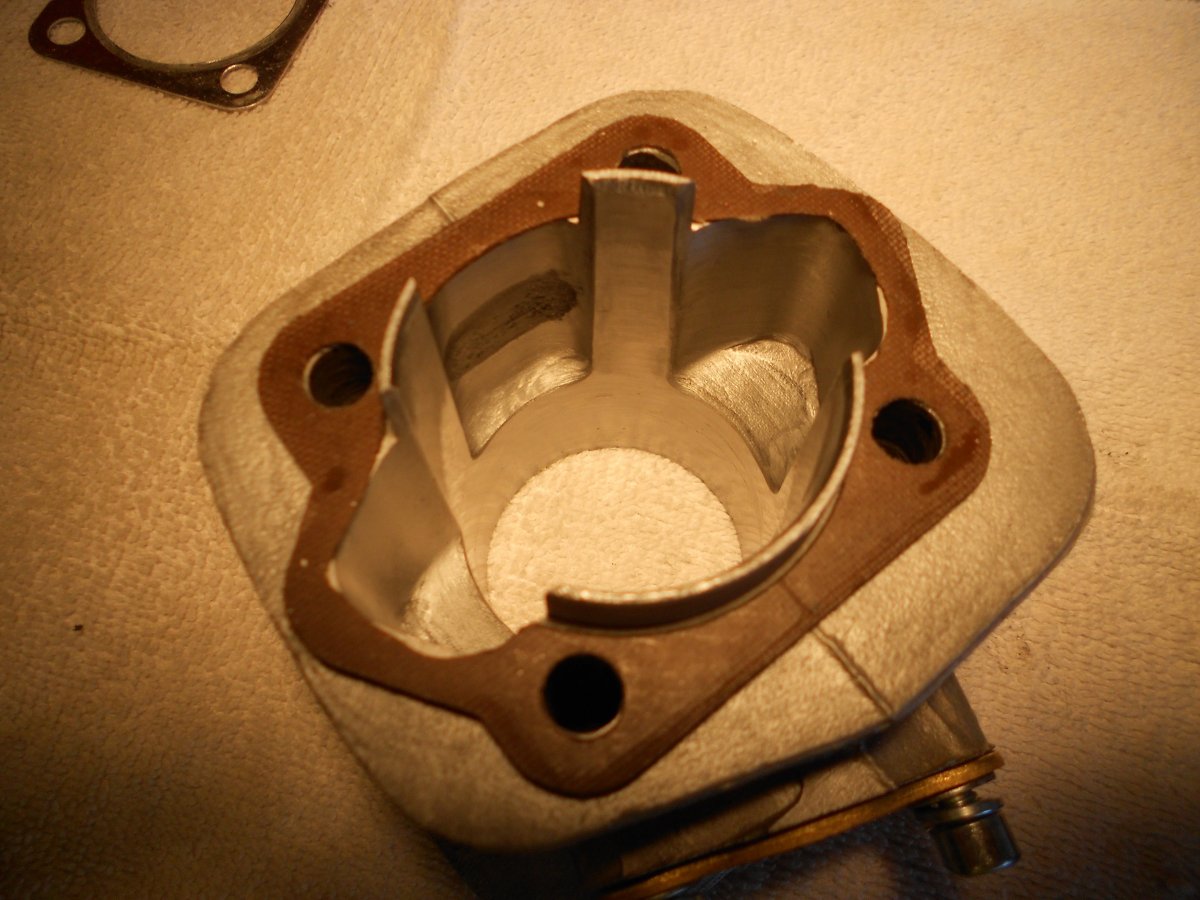

Ported cylinder, degree wheel, zeda piston and scale

Not messing around this time. Used the degree wheel to port the cylinder and the scale is to...

Nachi bearings, clutch shaft, clutch actuator rod and seals.

Seals came from Bicycle Motor Works.

Clutch parts are from flying horse.

Bearings are from...

Clutch parts are from flying horse.

Bearings are from...